Page 2

Use the following adjustment procedures should the lift not function as described in the certi

fi

cation checklist.

These procedures must be followed in order for the lift to be FMVSS 403/404 compliant.

• Vehicle movement is prevented unless the platform is fully stowed.

1. Verify lift stowed signal - pin 7 on the pump module has a +12 volt signal OR pin 9 has a ground signal

(depends on interlock used).

2. Refer to the interlock installation instructions.

• Lift operation shall be inhibited unless the vehicle is stopped and vehicle movement is prevented.

1. Verify vehicle secure signal (pin 6) has a +12 volt signal.

2. Refer to the interlock installation instructions.

• The platform will not fold/stow when at least 50 pounds is on the platform.

1. Position the platform at the

fl

oor level loading position.

2. Loosen the locknut on the dual relief valve adjustment (do not remove locknut). See illustration below.

3. Turn the adjustment screw counter clockwise until the platform does not fold when the Fold button is

pressed.

4. Turn the adjustment screw clockwise in 1/4 turn increments and press the Fold button until the platform

folds completely (Note: return the platform to

fl

oor level position after each attempt to fold the platform).

5. Turn the adjustment screw an additional 1/8 turn after the platform folds successfully.

6. Tighten the locknut without moving the adjustment screw.

7. Verify the platform will not stow with at least 50 pounds on the platform.

• The inner rollstop will not raise if occupied by at least 25 pounds.

- Call Product Support

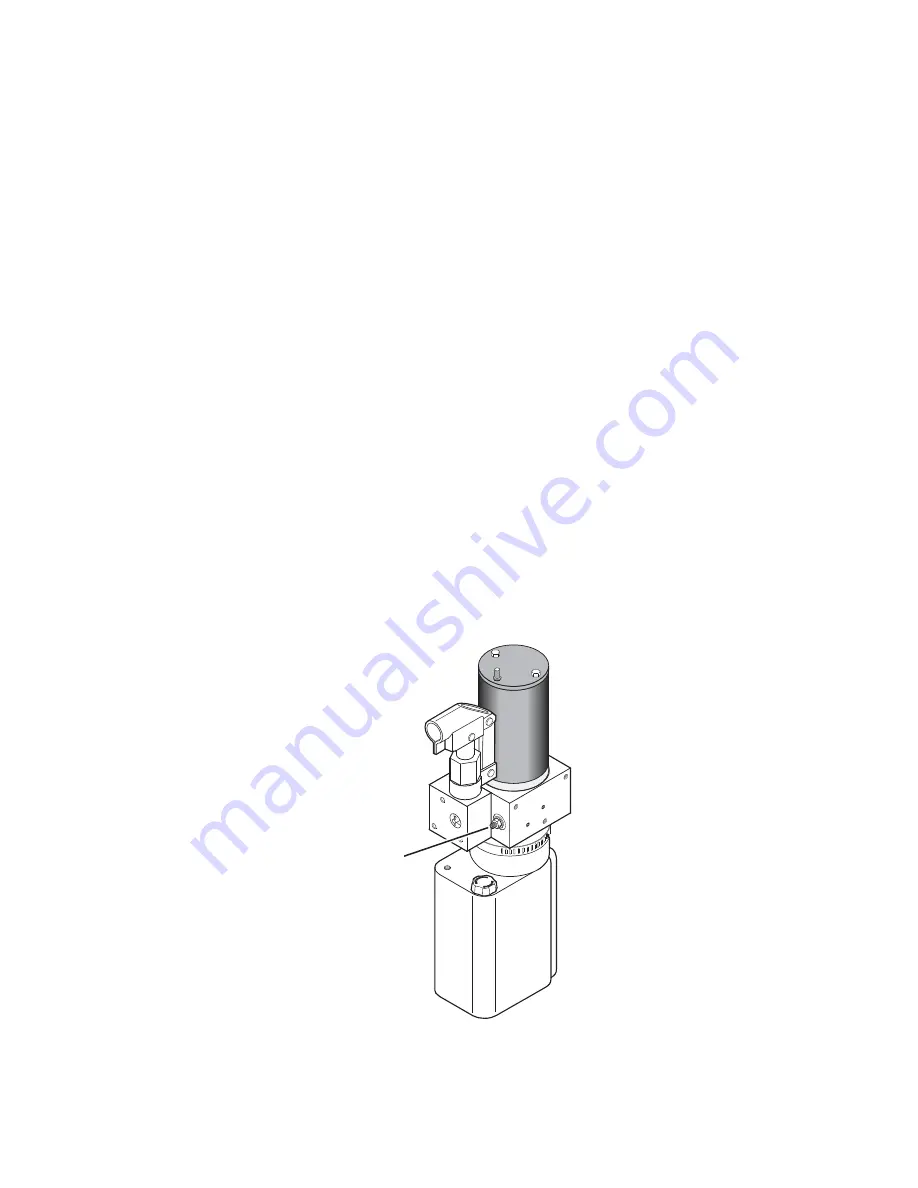

Dual Relief Valve

Adjustment

(Located beside Backup Pump)

Certi

fi

cation Checklist Diagnostic Procedures