4

26. Never allow anyone to stand under a suspended

load.

27. Exposed areas of capstan shafts are dangerous.

Clothing and other items may become tangled and

wrapped around the shaft when rotating. Appropriate

guarding should be installed to prevent any part of

the body or clothing from contacting the shaft

when it is rotating. Failure to provide appropriate

guarding could result in property damage, injury or

death.

WARNING: This emblem is used to warn

against hazards and unsafe practices which

could result in severe personal injury or death

if proper procedures are not followed.

CAUTION: This emblem is used to warn

against potential or unsafe practices which

could result in personal injury or product or

property damage if proper procedures are not

followed.

CAUTION

Safety information callouts used in this manual:

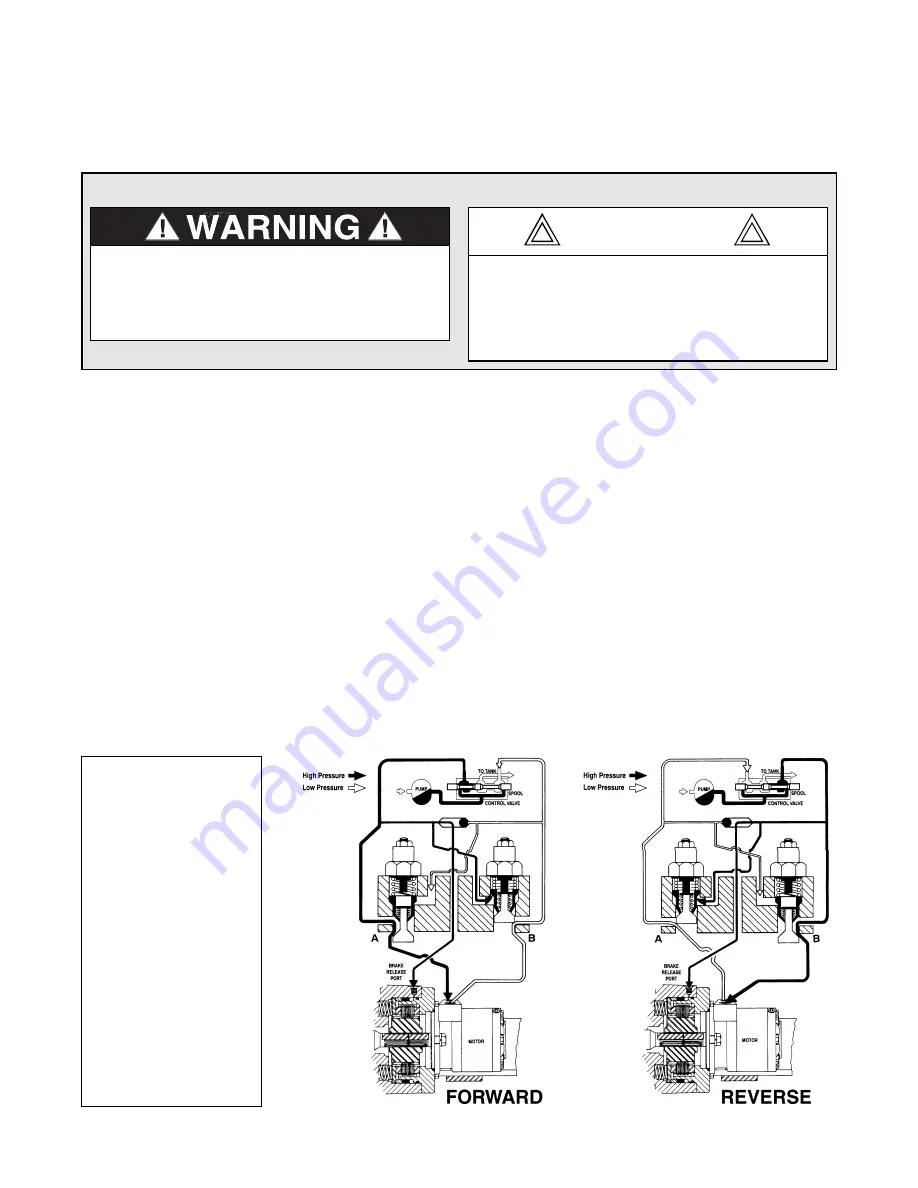

THEORY OF OPERATION

The PCD24B capstan drive is made up of the follow-

ing sub-assemblies and parts:

1. Hydraulic motor and brake valve block with

cartridges.

2. Static brake assembly.

3. Planetary gear set.

4. Output shaft and bearings.

The static brake assembly is a multiple disk pack which

is spring applied, hydraulically released, and equipped

with a solid hub coupling the motor shaft to the plane-

tary sun gear. This means that the static brake is

applied when the drive is stopped, keeping the output

shaft from rotating in either direction. Also, the motor

cannot operate the drive in either direction until the brake

has been released.

In operation, the static brake must be hydraulically

released when the drive is operated in either direction.

When the control valve handle is moved in either direc-

tion, hydraulic pressure is piloted to the brake release

piston and routed to the motor at the same time. Oil

flow out of the motor is initially blocked by one of the

counterbalance cartridges. As hydraulic pressure

increases, the static brake is released. At this time, oil

flow out of the motor is still blocked. As pressure con-

tinues to increase, the cartridge is piloted open and the

motor is allowed to turn. This sequence ensures the static

brake is completely released before any rotation occurs,

resulting in minimal wear of the friction disks in the brake

assembly. The extent to which the cartridge opens will

determine the amount of oil that can flow through it and

the speed of the output shaft. Increasing the flow of oil

to the drive will cause the pressure to rise and the open-

ing in the cartridge to enlarge, allowing more oil to flow

and increasing the speed of the output shaft. Decreasing

this flow causes the pressure to lower, decreasing the

opening in the cartridge and slowing down the output

shaft. When the control valve is returned to center and

oil flow is stopped, motor rotation stops and the static

brake is fully applied by the brake springs.

Disc brake (static parking

brake) releases at approx.

390 psi (2,690 kPa) at no

load.

Dual cartridge counter-

balance valve opens at

aprox. 960 psi (6,620 kPa) at

15 gmp (57 Lpm).

Dual cartridge counter-

balance valve opens at

approx. 1,580 psi (10,890

kPa) at 30 gpm (114 Lpm).

NOTE: Pressures shown

above are

Δ

P across the

motor.