-11-

ACCESSORIES AVAILABLE:

N80CB DRIVER MAINTENANCE INSTRUCTIONS

Worn driver causing poor quality or loss of power:

•

Wear on the driving tip will affect the nail drive, giving symptoms of bent and incompletely driven

nails, and damaged nail heads.

•

The driver length may be adjusted to allow the driving tip to be redressed to compensate for

wear. Heat and precise measurement are required. Contact a qualified service technician for

this adjustment.

•

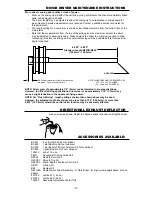

The length setting for a new driver is shown below. Measurement is from the bottom face of the

main piston.

•

Note that the measurement from the top of the piston gives the maximum amount the driver

may be adjusted to allow redressing. Always extend the driver the minimum required to allow

redressing to restore the driving end; several redressings will be possible before this maximum

depth is reached.

Loosen screw as shown. Adjust to desired exhaust direction and tighten screw.

3/8" (9.5mm) maximum limit of driver recessed

into piston. Do not exceed this limit

NOTE: WHEN DRESSING IS REQUIRED, USE

.015" - .025 x 45˚ CHAMFER

(.38 - .64mm x 45˚ CHAMFER)

SEE NOTE

6.000" – 6.020"

Standard Length N80CB/N80P

(152.4mm – 152.9mm)

NOTE: Driver wear of approximately 1/8” (3mm) can be tolerated in most applications.

However, in difficult driving applications, driver wear or approximately 1/16” (1.5mm) may

cause a slight reduction in the apparent driving power.

NOTE: For “Flush-Driving”, length settings shorter than shown above may be used.

However, the adjusted length should never be less than 5.705” (144.9mm), or more than

6.055” (153.8mm), otherwise normal nailer function may be adversely affected.

BC601

4 oz. Bostitch Air-Tool Lubricant

BC602

1 pint Bostitch Air-Tool Lubricant

BC603

1 pint Bostitch “Winter-Formula” Air-Tool Lubricant

BC604

1 quart Bostitch Air-Tool Lubricant

100679

Lube 1 lb. can

SEQ1

Sequential Trip Conversion Kit

N80K2

Remote Control Kit

N80CK1

Smooth Trip Kit

N80CK2

Dial-A-Depth

TM

Fastener Control Kit

ORK11

O-Ring Kit

BK3

Bumper Kit

N80154A Replacement Driver Assembly - A “Hard Driver” for high volume applications, such as

pallets

851325

Loctite 271 (.02 oz.)

831385

Loctite 242 (.02 oz.)

105005

Assembly, Adjustable Contact Trip

6.000” - 6.020”

Standard Length N80CB/N80P

(152.4mm - 152.9mm)

DIRECTIONAL EXHAUST DEFLECTOR