Page | 17

Problem

Possible Cause

Solution

Motor fails to start.

•

Overload Protection Device

is disengaged to protect the

log splitter from being

damaged.

•

Switch off the motor and

unplug the power cable. Let

motor cool down for half an

hour and restart. If this does

not solve the problem, call

your dealer for customer

support.

The log splitter won’t split logs.

•

Log is improperly positioned.

•

The size or hardness of the

log exceeds the machine’s

capacity.

•

Wedge cutting edge is blunt.

•

Insufficient hydraulic oil.

•

Unauthorized adjustment

was made on the Maximum

Pressure Limiting Screw.

Lower maximum pressure

rating was set.

•

Refer to

Operation

section

for log loading.

•

Reduce the log size before

splitting

•

Refer to “Sharpening The

Wedge” in the

Maintenance

section.

•

Locate leak(s). Contact the

dealer.

•

Contact the dealer.

Log ram jerks, vibrates or does not

move.

•

Unit is not placed on level

ground.

•

Lack of hydraulic oil

•

Excessive air in the

hydraulic system.

•

Log splitter is over forced.

•

Reposition the log splitter

to ensure that the wheel

end of the unit is no

higher than the other end.

•

Check oil level for possible

oil refilling.

•

Ensure vent plug is loose

during operation

•

Turn off and restart the unit.

•

Contact the dealer.

Oil leaks from the hydraulic system

or from other points.

•

Air is sealed in hydraulic

system while operating.

•

Vent plug is not tightened

before moving the log

splitter.

•

Oil drain bolt is not tight.

•

Hydraulic fitting(s) and/or

seal(s) are worn.

•

Loosen vent plug before

operating the log splitter.

•

Tighten the vent plug before

moving the log splitter.

•

Tighten the oil drain bolt.

•

Contact the dealer.

TROUBLESHOOTING

Содержание ES7T20

Страница 2: ......

Страница 5: ...Page 2...

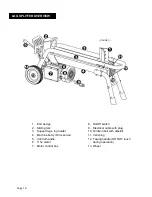

Страница 22: ...Page 19 EXPLODED DIAGRAM PARTS LIST...

Страница 26: ...Page 23 1 Log Splitter 1 Owner s Manual 1 Control handle 1 Hex Key PACKING LIST...

Страница 27: ...Page 24...