Troubleshooting

GREENSTAR WIRING CENTRE – 6720880441 (2018/01)

16

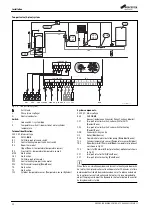

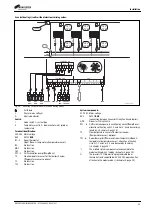

Code switch I

The system type is set on the module using

code switch I

:

• 3-way valve (Y-plan) system: code switch I set to

Y

• Two-port valve (S-plan) system: code switch I set to

S

• 3 central heating circuits without electronic mixing valves:

– Module for heating circuits 1, 2 and 3 = set code switch 1 to

2

– Module for heating circuits 4, 5 and 6 = set code switch I to

3

• 2 heating circuits without electronic mixing valves and one cylinder

charging circuit: set code switch I to

1

Temperature switch II

WARNING:

Risk of scalding from hot water!

▶ If water temperatures are set above 60 °C or thermal disinfection is

engaged (where temperature switch II is temporarily over 60 °C), a

mixer must be installed.

Automatic legionella protection function: this function becomes active if

the DHW cylinder does not reach a temperature of 60 °C during a 5-day

period. This function automatically heats the cylinder 65 °C for 2 hours.

The

cylinder setpoint temperature

is adjusted using

temperature

switch II

:

• The temperature in the DHW cylinder can be adjusted in increments

of 5 °C.

• To ensure an economical and comfortable DHW temperature and

sufficient protection against bacterial contamination in the DHW

cylinder,

temperature switch II

should be set to at least 60 °C.

• A maximum setpoint temperature 75 °C is available: set the

temperature switch to

max

(two valid switch positions)

In the event of the hot water dial indicator flashing green, adjust the hot

water temperature selector dial in small increments to select a valid

temperature setting. Only temperatures indicated on the control dial can

be selected. Once set correctly, the hot water temperature selector dial

indicator will cease to flash.

System and module commissioning

1. Set the system type for the module using code switch

I

.

2. Set the cylinder temperature using temperature switch

II

.

-or-

Set temperature switch

II

to

off

.

3. Switch on the power supply (230 V AC) for the entire system, the

Greenstar Wiring Centre and the boiler.

When the status indicator of module lights up green:

4. Commission and set up the boiler and control system accessories in

accordance with the installation instructions supplied with those

products.

5

Troubleshooting

Use only original spare parts. Damage caused by the use of spare parts

not supplied by the manufacturer are excluded from the warranty.

▶ If a fault cannot be rectified, please contact your local service

engineer.

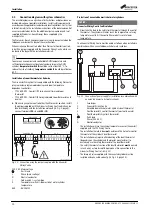

5.1

Status indicator

The indicator shows the operating status of the module.

Fig. 26 Module status indicator

Table 4 Troubleshooting

5.2

Replacing the fuse

DANGER:

Danger to life due to current!

Touching live parts can result in an electric shock.

▶ Electrically isolate the boiler and system components. Secure against

unintentional reconnection and make sure the power supply is

disconnected.

Status indicator

Possible cause

Remedy

permanently off

(at code switch I)

Code switch on

0

▶ Set the code switch

(

Power supply

interrupted

▶ Turn on the power supply.

Fuse is defective

▶ With the power supply turned

off, replace the fuse

(

Short circuit in the BUS

connection

▶ Check BUS connection and

repair if required.

permanently red

(at code switch I)

Internal fault

▶ Replace module.

Flashing red (on

code switch I)

Code switch in invalid

position or in

intermediate position

▶ Set the code switch

(

Flashing green (on

code switch I)

Maximum cable length

for BUS connection

exceeded

▶ Make shorter BUS

connection.

Temperature sensor is

defective

▶ Replace the temperature

sensor.

Temperature switch in

invalid position or in

intermediate position

▶ Adjust the temperature

switch (

No signal from the 2-

way zone valve limit

switch received within

30 seconds after

commissioning

▶ Check the cabling between

the zone valve and zone valve

limit switch

Temperature for

legionella protection not

reached in the 2-hour

phase

▶ Insufficient heat transfer via

the cylinder ignition coil, or;

▶ Check the sensor position on

the cylinder.

Permanently

green (at code

switch I)

No fault

Normal operation

0

1

2

3

4

S

Y

I

off

40

50

60

70

max

II

II

0 010 013 180-001