12.

Maintenance

Service

Maintenance performed by unauthorized

personnel may result in misplacing of the

internal components which could cause serious hazard.

We recommend that all tool service be performed by a

BOSCH factory service center or authorized BOSCH

service station.

Contact your BOSCH service center for instructions and the

following user replaceable parts; o-rings, bumpers, and

driver blades.

For all other repairs contact your BOSCH service center.

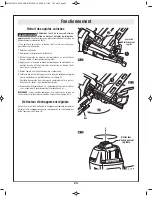

Cleaning

When cleaning a tool be careful not to

disassemble any portion of the tool since

internal components may be misplaced or safety

components may be improperly mounted.

Certain

cleaning agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts and o-rings.

Do not attempt to clean by inserting

pointed objects through openings.

Sharp

edges may damage internal components causing a serious

hazard.

Ventilation openings, the work contact element, and the

trigger must be kept clean and free of foreign matter.

Periodically clean the tool with compressed air.

Clean the magazine. Remove metal or wooden chips which

may have accumulated in the magazine. Periodically clean

magazine with compressed air.

Storage

When not in use, the tool should be disconnected and

stored in the storage case in a warm and dry place. When

tool will not be in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

Do not store the tool in a cold weather environment.

Keep out of reach of children and

personnel unfamiliar with tool operation.

Lock the storage area. Tools are dangerous in the hands of

personnel unfamiliar with the tool.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

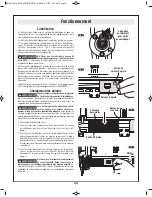

ACTION

WHY

HOW

Drain air line filter

daily.

Prevent

accumulation of

moisture

and dirt.

Open manual

valve.

Keep lubricator

filled

Keep the Stapler

lubricated

Fill with BOSCH

pneumatic tool

lubricant.

Clean filter element

- then blow air

through filter in

direction opposite

to normal flow.

Prevent clogging

of filter with dirt.

Follow

manufacturer's

instructions.

Clean magazine

and feeder

Prevent a jam.

Blow mechanism

clean daily.

Keep work contact

element working

properly

Promote operator

safety and efficient

tool operation.

Blow clean daily.

Lubricate the tool.

Extend tool life.

Place 2-3 drops of

lubricant

into the tool as

directed.

Drain air

compressor.

Keep water out of

tool.

Open valve on air

compressor tank.

BM 2610957389 04-09:BM STN150-18 06-09 6/17/09 7:45 AM Page 12