22

/84

Bosch Rexroth AG

LTU350/1 | 3 609 929 B47/2008-12

Language packs

The language pack for the LTU350/1 is

uploaded to the controller using the BS350

operating program. This is done via the menu

item “Configuration | HMI SE/CS” in the

BS350.

LED display and reset button

There are three LEDs on the front panel of the

servo amplifier to indicate the operating

state.

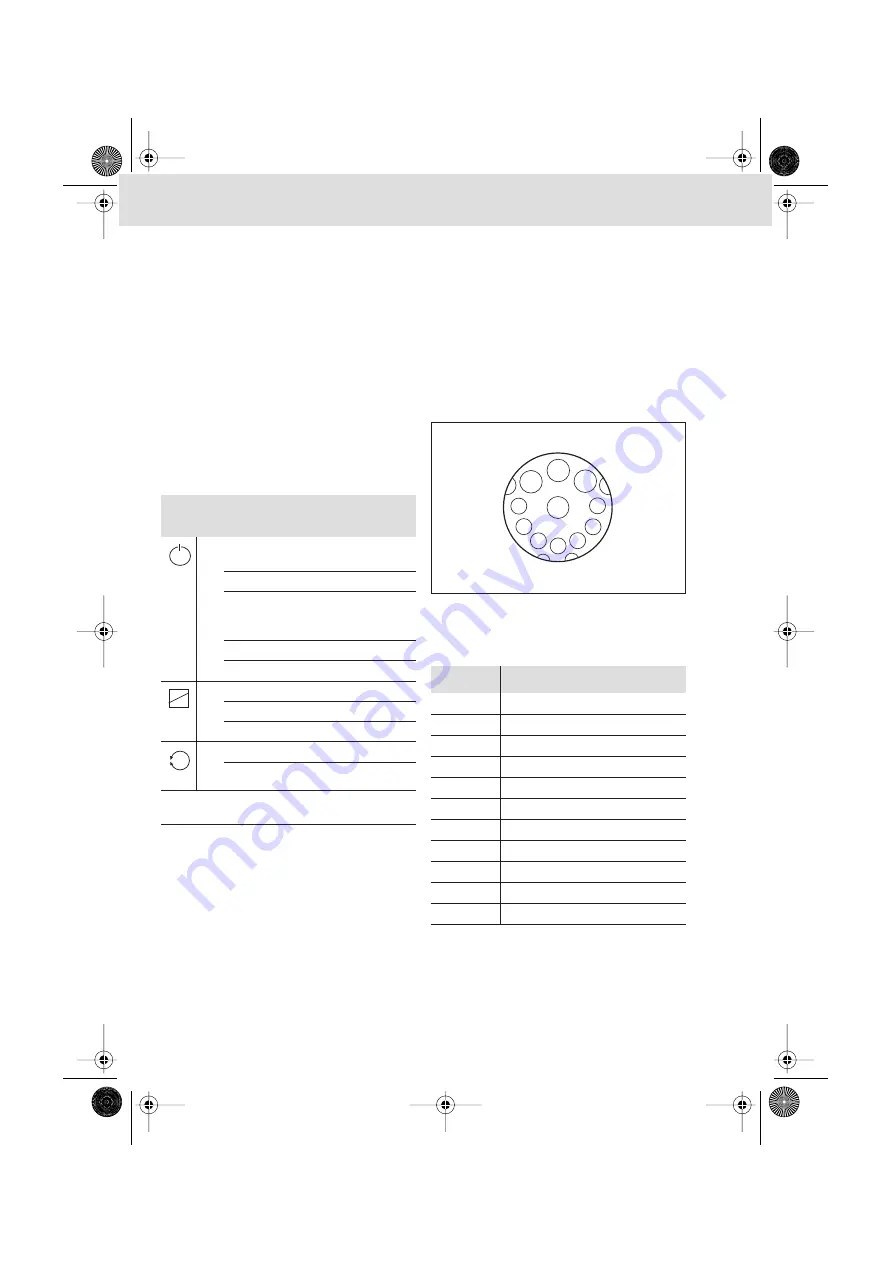

XDS1 interface for handheld

nutrunner

The tightening spindle is connected to the

servo amplifier via a spindle connecting cable

that is connected to the 11-pin socket. The

power supply for the motor, logic supply, and

transmission of interface signals is provided

via this cable.

Fig. 3: Socket, view from front side

Table 5

LED/

button

Display Diagnosis

BTB

Off

No power supply or LTU is in

download mode

Green

Ready for operation

Green,

flashing

Not ready for operation, but

no system error; emergency

OFF has been triggered

Red

System error

Orange

VM supply module not ready

TS

Off

Motor contactor open

Green

Ready for operation

Red

Motor contactor error

FG

Off

No servo amplifier release

Green

Servo amplifier release

Reset

When pressed, a reset is performed to

reinitialise the tightening channel

Table 6

Pin

Signal assignment

1

CAN-L

2

CAN-H

3 24

V

4 GND

5 HS

6 SAMI-B

7 SAMI-A

U

Phase U

V

Phase V

A

Phase W

PE

Protective earth/shield

V

1

2

3

4

5

6

7

PE

U

A

∆

LTU350.book Page 22 Tuesday, December 16, 2008 12:24 PM