Rexroth EcoDrive Cs

Identification

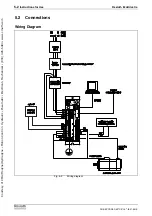

2-3

DOK-ECODR3-DKC*CS*UL**-IB01-EN-P

Drive Controllers without Master Communication (Basic Devices)

1.

Product

1.1

DKC . . . . . . . . . . = DKC

2.

Line

2.1

10 . . . . . . . . . . . . . . . . . . = 10

3.

Design

3.1

3 . . . . . . . . . . . . . . . . . . . . . . . . = 3

4.

Rated current

4.1

4 A . . . . . . . . . . . . . . . . . . . . . . . . . . = 004

4.2

8 A . . . . . . . . . . . . . . . . . . . . . . . . . . = 008

4.3

12 A . . . . . . . . . . . . . . . . . . . . . . . . . . = 012

4.4

18 A . . . . . . . . . . . . . . . . . . . . . . . . . . = 018

5.

DC-bus nominal voltage

5.1

DC 300 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = 3

6.

Firmware

6.1

Multi interface general purpose . . . . . . . . . . . . . . . . = MGP

7.

Firmware version

7.1

e.g., 01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = 01

8.

Nature of the firmware

8.1

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = V

9.

Firmware release status (update) (00 to 99)

9.1

Release status (the currently valid status

= status of the items list delivered) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = RS

Illustration example:

DKC10.3-XXX-3

1 2 3 4

6 7 8 9

1

0

5

1 2 3 4

6 7 8 9

2

0

5

1 2 3 4

6 7 8 9

3

0

5

1 2 3 4

6 7 8 9

4

0

5

Example:

Abbrev.

Column

D K C 1 0 . 3 - 0 0 4 - 3 - M G P - 0 1 V R S

Fig. 2-3:

Type code for drive controllers without master communication (basic

devices)

Master Communication

1.

Product

1.1

ECM . . . . . . . . . = ECM

2.

Line

2.1

1 . . . . . . . . . . . . . . . . . . . = 01

3.

Design

3.1

1 . . . . . . . . . . . . . . . . . . . . . . . . . = 1

4.

Interface

4.1

CANopen. . . . . . .. . . . . . . . . . . . . . . . = CN01

4.2

DeviceNet (open style). . . . . . . . . . . . . = DN01

4.3

DeviceNet (micro style) . . . . . . . . . . . . = DN02

4.4 none (cover) . . . . . . . . . . . . . . . . . . . . = NNNN

4.5

PROFIBUS-DB. . . . . . . . . . . . . . . . . . . .= PB01

5.

Other design

5.1

none . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = NN

Illustration example:

ECM01.1

1 2 3 4

6 7 8 9

1

0

5

1 2 3 4

6 7 8 9

2

0

5

1 2 3 4

6 7 8 9

3

0

5

1 2 3 4

6 7 8 9

4

0

5

Example:

Abbrev.

Column

E C M 0 1 . 1 - P B 0 1 - N N

Fig. 2-4:

Type code for master communication

Courtesy

of

CMA/Flodyne/Hydradyne

▪

Motion

Control

▪

Hydraulic

▪

Pneumatic

▪

Electrical

▪

Mechanical

▪

(800)

426-5480

▪

www.cmafh.com