English - 6

1 609 929 599 • TMS • 17.01.01

Check for correct mains voltage: The voltage

of the power source must agree with the voltage

specified on the nameplate of the machine.

Equipment marked with 230 V can also be con-

nected to 220 V.

Switching on: Slide the On/Off switch 2 for-

ward.

Switching off: Release the On/Off switch 2.

Locking:

Slide the On/Off switch 2 for-

ward and press down to the front

until it latches.

Switching off: Press down the On/Off switch 2

to the rear - the switch springs to

the off position.

☞

Test run!

Check the grinding tool before use. The

grinding tool must be flawlessly mounted

and be able to rotate freely. Perform a test

run of at least 30 seconds without load. Do

not use damaged, out-of-round or vibrating

grinding tools.

Starting Current Limiting (Type C/CE)

As a result of soft starting, a 13-A fuse is ade-

quate.

A machine without starting current-limiter re-

quires a higher fuse protection.

Constant Electronics (Type C/CE)

The constant speed electronics hold the speed at

no-load and when under load nearly constant and

ensure uniform working performance.

Overload Protection

When overloaded, the motor comes to a stop.

Relieve the load on the machine immediately and

allow to cool for approx. 30 seconds at the high-

est no-load speed.

Preselect the required speed using the thumb

wheel 1 according to the table following the sec-

tion “Product Specification” (reference values).

■

Clamp the workpiece if it does not remain

stationary due to its own weight.

■

Do not load the machine so heavily that it

comes to a standstill.

■

Roughing and cutting discs become very

hot while working; do not touch until they

have cooled.

Rough Grinding

With an approach angle of 30° to

40°, the best roughing results can

be achieved. Move the machine

back and forth with moderate pres-

sure. In this manner, the work piece

will not become too hot, does not

discolour and no ridges are formed.

Never use a cutting disc for roughing.

Flap disc

With the flap disc (optional extra), curved sur-

faces and profiles (contour sanding) can be

worked.

Flap discs have a considerably higher service life

than sanding sheets, lower noise level and lower

sanding temperatures.

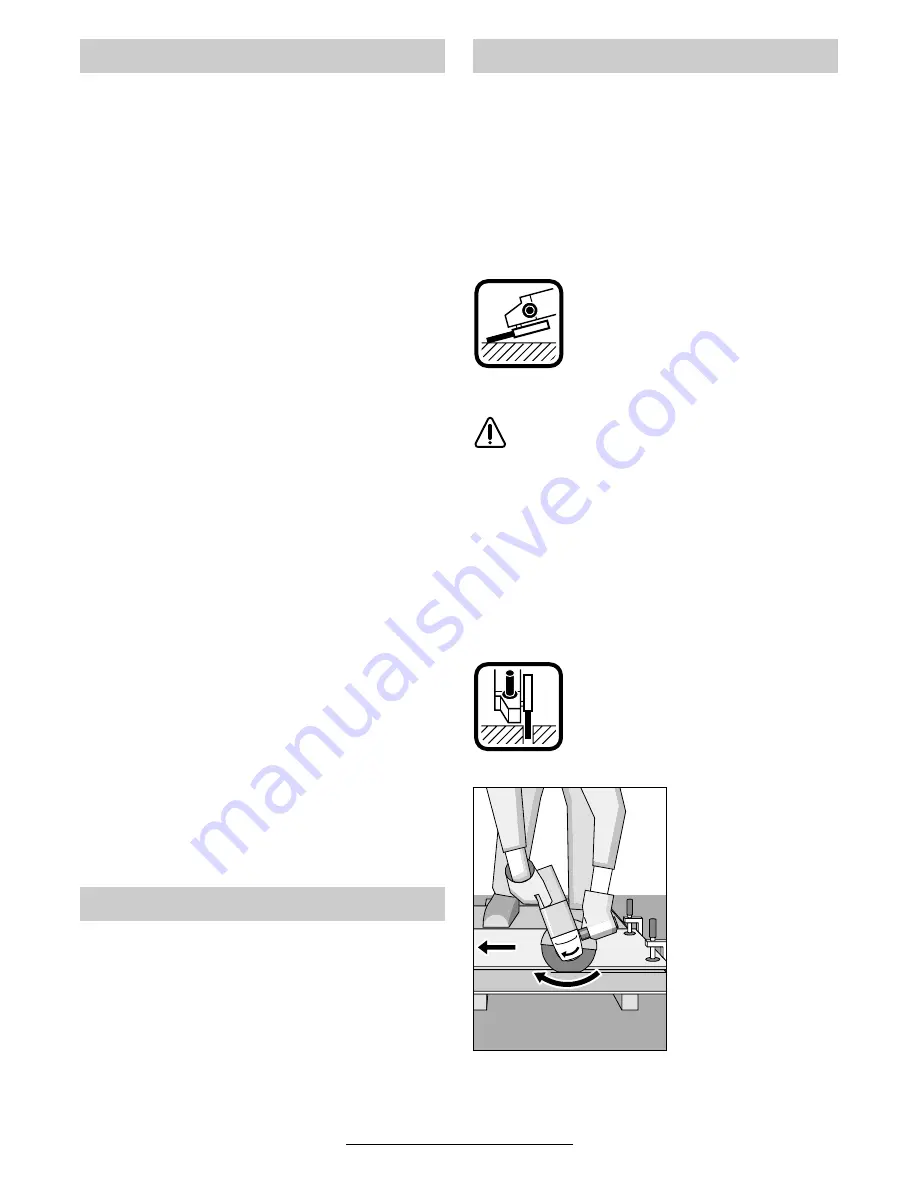

Cutting

When cutting, do not press, tilt or

oscillate. Work with moderate ad-

vancing that is adapted to the mate-

rial being worked.

Do not brake coasting cutting disks

with side pressure.

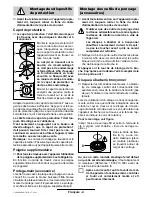

Important is the di-

rection in which cut-

ting is performed.

The machine must

always work opposite

to the direction of ro-

tation. Therefore,

never move the ma-

chine in the other di-

rection! Otherwise,

the danger exists of it

being pushed un-

controlled out of the

cut.

Initial Operation

Speed Selection (Type CE)

Operating Instructions

Содержание GWS 14-125 C

Страница 3: ...1 609 929 599 01 01 ...