19

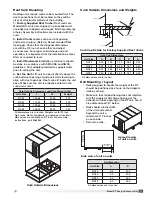

Model RT Energy Recovery Unit

Electric Heater Application/Operation

Factory installed electric heaters may be optionally

supplied for energy wheel preheating. The optional

electric preheater is positioned upstream of the air

intake filters and its primary function is to prevent

frost accumulation on the energy wheel. Electric

heaters are available in 208, 230, or 460 VAC (refer

to heater nameplate for voltage). An optional

tempering electric heater may be installed as a

supplementary heat source and is located as shown

in Subassemblies/Optional Electric Heat.

Optional Accessories

Preheaters:

Preheaters are standard as two-stage,

step control. Step control heaters are designed with

multiple stages made up of equal increments of

heating capability. For example, a 10 kW heater with

two stages will be composed of two 5 kW stages.

Preheaters are single point wired at the factory.

A temperature sensor (with field adjustable set

point) is mounted in the outdoor airstream after the

preheater to turn the preheater on. See Frost Control

Application/Operation for typical set points. If the

temperature falls below the set point and the wheel

pressure drop sensor is triggered, the first stage of

the preheater will turn on. If the first stage does not

satisfy the set point, the second stage will also turn

on.

See also Subassemblies/Electric Heaters

Post-heaters:

Post-heaters are standard as

SCR control; see unit specific wiring diagram. A

temperature sensor (with field adjustable set point)

is mounted in the outdoor airstream after the post-

heater to turn the post-heater on. A SCR heater

provides an infinitely modulating control of the heat to

provide an accurate discharge temperature. A call for

heat is required.

Post-Heater Control Panel:

The post-heater is

not single point wired to the RT control center.

Separate power must be supplied to the post-

heater disconnect (located in unit control center).

See Access Door Descriptions and Locations for

access to post-heater control panel. For Model RT,

the exhaust filters must be removed from the unit to

access.

Service Outlet

120 VAC GFCI service outlet ships

loose for field installation. Requires

separate power source so power is

available when unit main disconnect is

turned off for servicing.

Vapor Tight Lights

Vapor tight lights provide light to each of the

compartments in the energy

recovery unit. The lights are wired

to a junction box mounted on the

outside of the unit. The switch to

turn the lights on is located in the

unit control center. The switch

requires a separate power source

to allow for power to the lights

when the unit main disconnect is

off for servicing.