6

2. COMPETITIVE ADVANTAGES

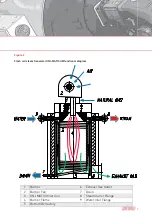

Figure 4

Safety and control instruments on an horizontal

UNI-MATIC UM steam generator.

Figure 5

Control panel for UNI-MATIC UM steam generator.

•

Two versions: vertical and horizontal

•

Maximum efficiency and high reliability

•

Easy maintenance.

The upper cover facili-

tates inspection and cleaning of the combus-

tion chamber and the internal parts of the

steam generator.

•

Fast to reach operating conditions.

Thanks

to the absence of thermal inertia, UNI-MATIC

UM steam generator is highly efficient in peri-

odic processes. It takes 2÷3 minutes to reach

operating condition after burner ignition.

•

High reliable supply of feeding water.

Feeding pump flow sections are made of

Kevlar

, a syntetic composite material which

guarantees maximum reliability and efficient

supply of feeding water.

•

Easy-to-use and reliable automatic combus-

tion

regulation with the following regulating

types:

•

“on/off” regulation

of gas fuel feeding

to the burner, burner air vent and feeding

water pump. Liquid fuel supply to burner

nozzle is achieved through electromagnetic

opening/closing valve.

•

two-stages regulation

(1st stage - min.

50%, 2nd stage - 100%), through regulation

of the amount of air and gas in the com-

bustion chamber, regulation of feed wa-

ter supply with two-position valves on the

fuel, air and water lines combined with on/

off regime of water and gas supply. Liquid

fuel supply to burner’s nozzle is achieved

through an opening/closing valve.

modulating regulation

of steam produc-

tion with 30-100% range, achieved with an

electronic control of air and fuel supply and

servocontrolled valves. Feeding water sup-

ply is regulated through plunger pump with

frequency transformer. Liquid fuel oil sup-

ply to burner’s nozzle is achieved through

opening/closing electromagnetic valve with

fuel pressure regulation through a bypass

valve.

•

Safety.

The quantity of water, and thus steam,

is limited, allowing therefore a high level of

safety for personnel if compared to standard

steam boilers types.