M W S - 8 3 M D

9

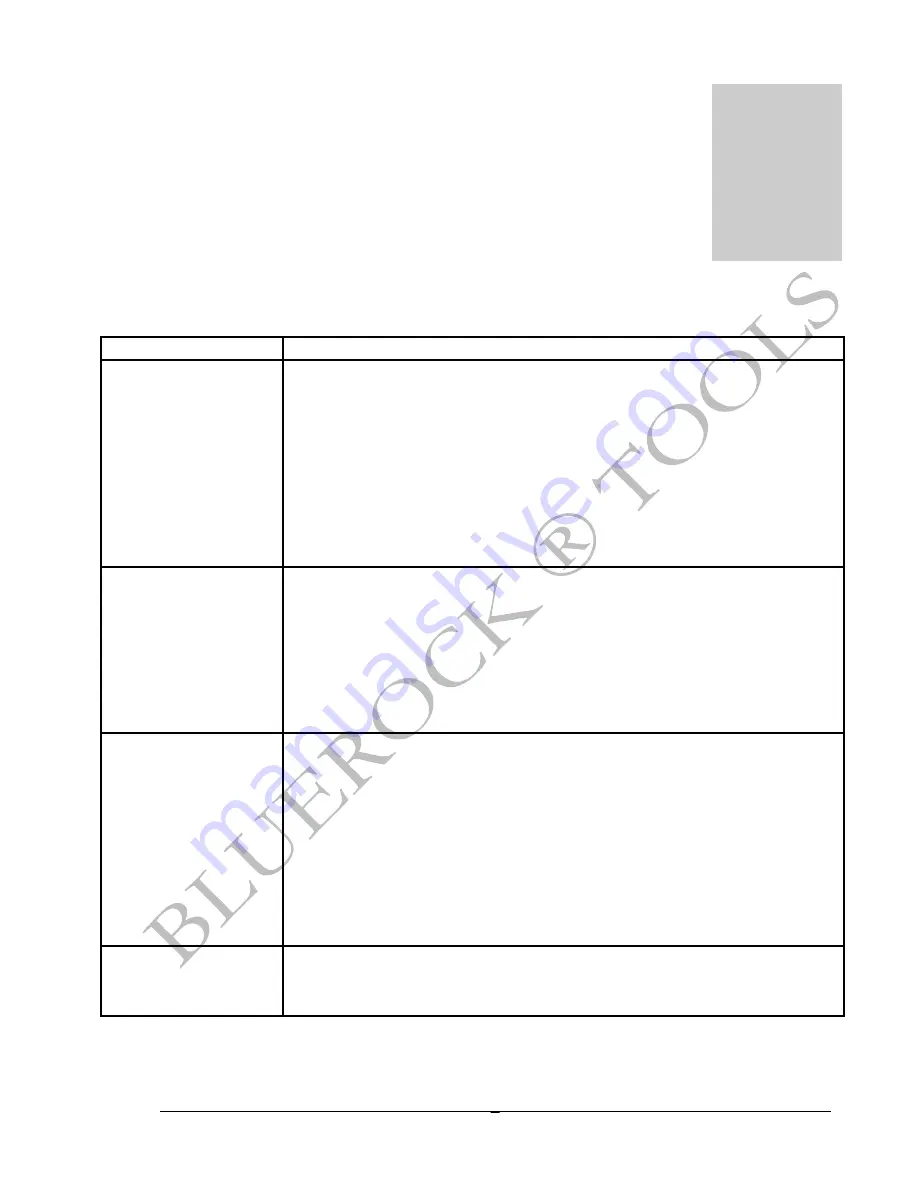

Troubleshooting

Problem

Solution

Wires get jammed in the

machine

There are a few possible fixes for this:

1: Loosen the top hand cranks to take pressure off springs to allow more room for

the springs to depress.

2: Check to make sure you are running the wire through the right channel. This

takes some time to figure out. Be patient when clearing the machine. Try the step

down method. Start in a larger hole than you think. Work your way down to a

smaller hole until ideal cut is made.

3: Only use the 1st two channels for running Romex®. They have the Rectangular

Guides.

4: The jacket on the wire you are trying to run is too thick. This machine will not

strip some wires where the jacket is too thick or the materials are too dense, such

as some underground plastics.

For smaller wire, the cut

in the wire jacket is not

in the center of the wire

The side adjustments could be out of alignment on the cutter rollers. The cutter

rollers on the top of the cutting assembly can adjust right to left. The cutting blades

should be centered in the middle of every roller. You can look down the middle of

every roller from front and back of the machine to see if the cutters are in the center.

If they are not, you can adjust the top cutter and rollers by adjusting the side bolts

(with the lock nut) to slightly shift the cutter/roller. Make sure you do not tighten the

bolts too much so the top cutter/roller assembly cannot raise and lower as wire

passes through. Think of these bolts as side stops only, just to keep the assembly

inline, so leave about 1mm gap in-between bolt and cutter/rollers.

The machine is

excessively loud and

makes grinding noise

These machines are generally on the noisier side as they use a gear drive system.

Firstly make sure the gears are greased. This can help with the noise. You can also

check the side adjustments as they could be out of alignment on the cutter rollers.

The cutter rollers on the top of the cutting assembly can adjust right to left/right.

The cutting blades should be centered in the middle of every roller especially those

on the left. You can look down the middle of every roller from front and back of the

machine to see if the cutters are in the center. If they are not, you can adjust the top

cutter and rollers by adjusting the side bolts (with the lock nut) to slightly shift the

cutter/roller. Make sure you do not tighten the bolts too much so the top

cutter/roller assembly cannot raise and lower as wire passes through. Think of

these bolts as side stops only, just to keep the assembly inline, so leave about 1mm

gap in between bolt and cutter/rollers.

The machine is not

cutting through the

entire jacket

Increase the tension on the top hand cranks. It is also possible that either you are

cutting wire that has too thick of a wire jacket or too dense a jacket. These jackets

may not be able to cut with this machine

Chapter

4

Содержание STRIPINATOR MWS-83MD

Страница 17: ...M W S 8 3 M D 14 Breakdown View...