Operating instructions

9

RECTIFYING MALFUNCTIONS

Malfunction

Cause

Remedy

•

Oil level rises

•

Drops of water in oil

•

Oil has milky colour

Water has collected in the crank

housing. Operating temperature is

not being reached because the

switch-on times are too short.

Change oil at once

Use a smaller compressor if neces-

sary

Water has collected in the crank

housing because the machine is

installed in a damp place.

Change oil at once

Select a dry place for installation

•

Motor cut-out has been triggered

Ambient temperature is too high

Ventilate the room or choose a

cooler place for installation

Supply voltage is wrong

Ask a qualified electrician to check

supply voltage and cross-sections of

the supply wiring.

Valves are defective

Replace the valves

Recommendation: call in BLITZ

Service-Department

•

Low air delivery

Suction filter clogged

Clean / replace suction filter

•

Excessive oil consumption

Wrong oil is being used

Check the type of oil

Wear between the piston-rings and

the cylinder walls

Replace the piston rings

Recommendation: call in BLITZ

Service-Department

•

Air is escaping through the safety

valve on the storage tank

Pressure switch is set too high

Check the pressure switch settings

•

Air is escaping from the depres-

surisation pipe on the pressure

switch or the solenoid valve

Non return valve is defective

Check the non return valve

Recommendation: call in BLITZ

Service-Department

•

Air is escaping from the depres-

surisation pipe of the pressure

switch or the solenoid valve whilst

compressor is running.

Air relief valve or pressure switch

dirty or defect

Check air relief valve

Recommendation Call in BLITZ

Service Department

•

Automatic condensate drain

(option) lets out water constantly

Automatic condensate drain is

polluted

Clean condensate drain (this can not

be claimed unter quaranty)

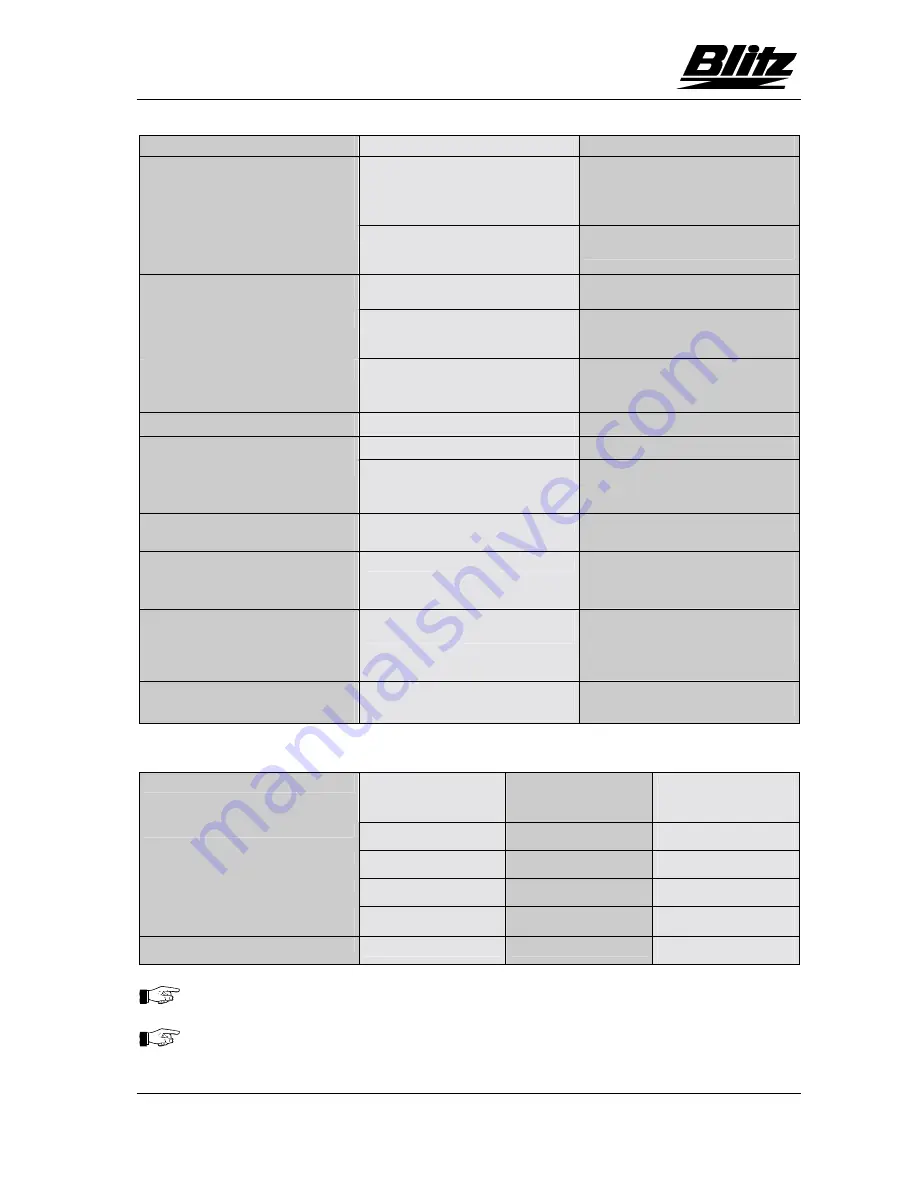

MAINTENANCE – OVERALL VIEW

After 100 working

hours, max. 6-8 weeks

after inital start

After 500 working

hours, at least once a

year

After 2000 working

hours, at least every 2

years

Change Oil

•

•

•

Check air filter for pollution

•

•

•

Regulate tension of the V-belt

•

•

•

Clean automatic condensate drain

(option) on air receiver

•

•

•

Check valve for erosion

•

The given intervals are based on experience. They can differ considerably depending on the

operating conditions.

Always tighten all screw connections that have been loosened during maintenance work.