MAINTENANCE & CLEANING

10

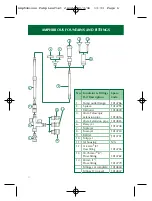

Fit the ceramic shaft to the pump housing with the radial groove and chamfered

end towards the pump housing. The shaft and its location in the pump housing

must be clean with no dirt or debris trapped between them. Trapped dirt may

affect the alignment of the impeller, which may damage the pump.

Slide rotor / impeller over ceramic shaft (with the impeller towards the pump

housing).

Lay ceramic thrust washer on top of the shaft. The faces of the shaft and thrust

washer must be clean. Any trapped dirt may cause uneven wear of the ceramic

washer and may allow the rotor to damage the pump.

Fit the centre bolt through centre holes of ceramic washer and shaft, ensuring the

copper centre bolt washer is fitted between the head of the bolt and ceramic thrust

washer.

Carefully tighten the LEFT HAND THREADED BOLT to a maximum torque of 2Nm.

The Impeller assembly should rotate freely after tightening. If it does not, dismantle

and re-check.

DO NOT LUBRICATE THE ROTOR ASSEMBLY WITH ANYTHING OTHER THAN

CLEAN WATER

Ensure impeller/rotor housing O ring seal is correctly seated in its recess and

reassemble motor to pump housing assembly. If the motor to pump housing is

difficult to fit, lubricate the O ring with clean water only.

The impeller assembly consists of the impeller/rotor, ceramic shaft, centre bolt,

copper washer, ceramic thrust washer and sealing O ring. Replacement impeller kits

are available for all models in the range.

RE-ASSEMBLY

3

4

5

6

7

9

7

6

5

4

3

Radial groove

chamfered end

Impeller

Amphibious Pump Leaflet 2.qxd 30/3/06 13:33 Page 12