104-A00 page 4/16

INSTALLATION

PUMP MOUNTING

A solid foundation reduces noise and vibration, and will

improve pump performance. On permanent installations it is

recommended the pumping unit be secured by anchor bolts

as shown in Figure 2. This arrangement allows for slight

shifting of position to accommodate alignment with the

mounting holes in the base plate.

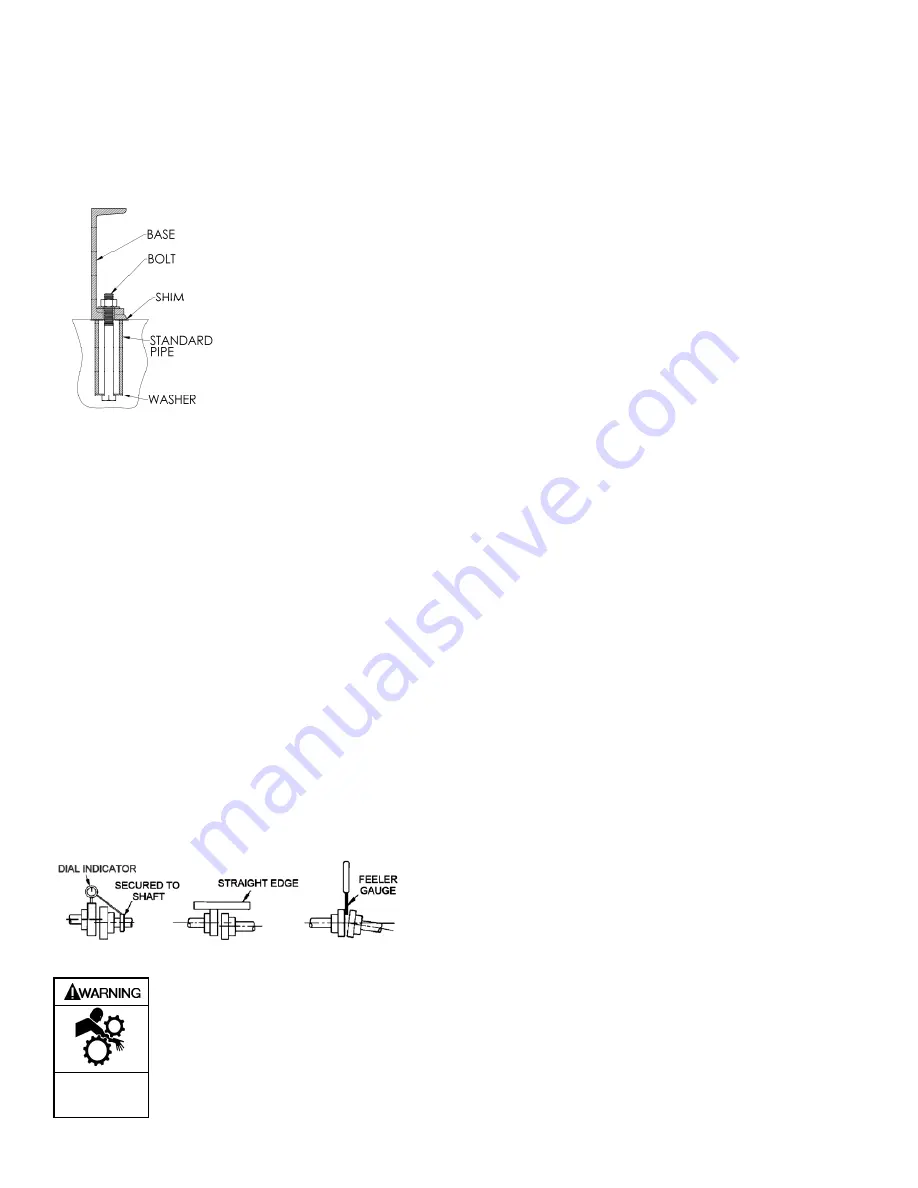

Figure 2 - Pipe Type Anchor

Bolt Box

For new foundations, it is

suggested that the anchor bolts

be set in concrete. When

pumps are to be located on

existing concrete floors, drill

holes into the concrete to hold

the anchor bolts.

When installing units built on channel or structural steel type

bases, use care to avoid twisting the base out of shape when

anchor bolts are tightened. Use shims under the edges of the

base prior to tightening the anchor bolts to level the base and

prevent distortion.

COUPLING ALIGNMENT

The pump must be directly coupled to a gear and/or driver

with a flexible coupling. Verify coupling alignment after

installation of new or rebuilt pumps. Both angular and

parallel coupling alignment MUST be maintained between the

pump, gear, motor, etc. in accordance with manufacturer’s

instructions. See Figure 3.

1. Parallel alignment: The use of a laser alignment tool or

dial indicator is preferred. If a laser alignment tool or dial

indicator is not available, use a straightedge. Turn both

shafts by hand, checking the reading through one

complete revolution. Maximum offset must be less than

.005" (.127 mm).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90° increments

around the coupling (four checkpoints). Maximum

variation must not exceed .005" (.127 mm). Some laser

alignment tools will check angular alignment as well.

3. Replace the coupling guards after setting alignment.

Figure 3 – Alignment Check

Do not operate

without guard

in place

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

PUMP ROTATION

NOTICE:

Confirm correct pump rotation by checking the pump

rotation arrows respective to piping flow direction. Do

not operate the pump in reverse rotation to reverse the

direction of flow.

1. Determine direction of flow where the pump will be

installed.

2. Confirm pump is installed in piping so that the flow will

pass through the pump from inlet to outlet. The inlet of

the pump has “INLET” cast in the cylinder and the outlet

has “OUTLET” cast in the cylinder.

3. Briefly “jog” pump with pump driver. Check rotation of

pump driver with respect to rotation arrow on pump.

A right-hand pump rotates clockwise with the intake on the

right side, when viewed from the driven end.

A left-hand pump rotates counterclockwise with the intake on

the left side, when viewed from the driven end.

TO CHANGE PUMP ROTATION

To reverse rotation, the pump must be disassembled then

reassembled with the shaft on the opposite side of the pump.

See the ‘Maintenance’ section for instructions.

CHECK VALVES

The use of check valves or foot valves in the supply tank is

not recommended with self-priming, positive displacement

pumps.

If the possibility of liquid backflow exists when the pump is

off, a check valve in the pump discharge piping is

recommended because the pump can motor in the reverse

rotation and create undue stress on all attached components.

Never start a pump when it is rotating in the reverse rotation

as the added starting torque can damage the pump and

related equipment. If a check valve is used, install it at the

pump discharge.

OPTIONAL JACKETED HEADS

Hot oil or steam can be circulated through jacketed heads by

connections at the jacket pipe plugs (73B) for heating highly

viscous liquids, or to "thaw out" liquids which have congealed

in the pumping chamber and packing area. Refer to the

'Technical Data' table on page 2 for the maximum allowable

steam pressure.

Make sure heat is applied early enough to sufficiently thin the

liquid before starting the pump. Liquids that congeal in the

relief valve chamber will make the valve inoperative.

Insulation of the pump with sufficient heat to the jackets will

usually thin the liquid in the relief valve chamber. Take

precautions to ensure the valve has free movement. It is

advisable to start the pump with an open discharge.

Drain the pump of all water when there is a possibility of

freezing. On models which have the steam connections on

the vertical center line, make the lower connection the outlet

so the water can be drained off. Models which have the

steam connections on the side also have a bottom drain plug.

Содержание SNP1.25

Страница 15: ...104 A00 Page 15 16 NOTES...