701-C00 Page 3/16

GENERAL INSTALLATION AND OPERATION

NOTICE:

Blackmer pumps must only be installed in systems

designed by qualified engineering personnel. System

design must conform with all applicable regulations and

codes and provide warning of all system hazards.

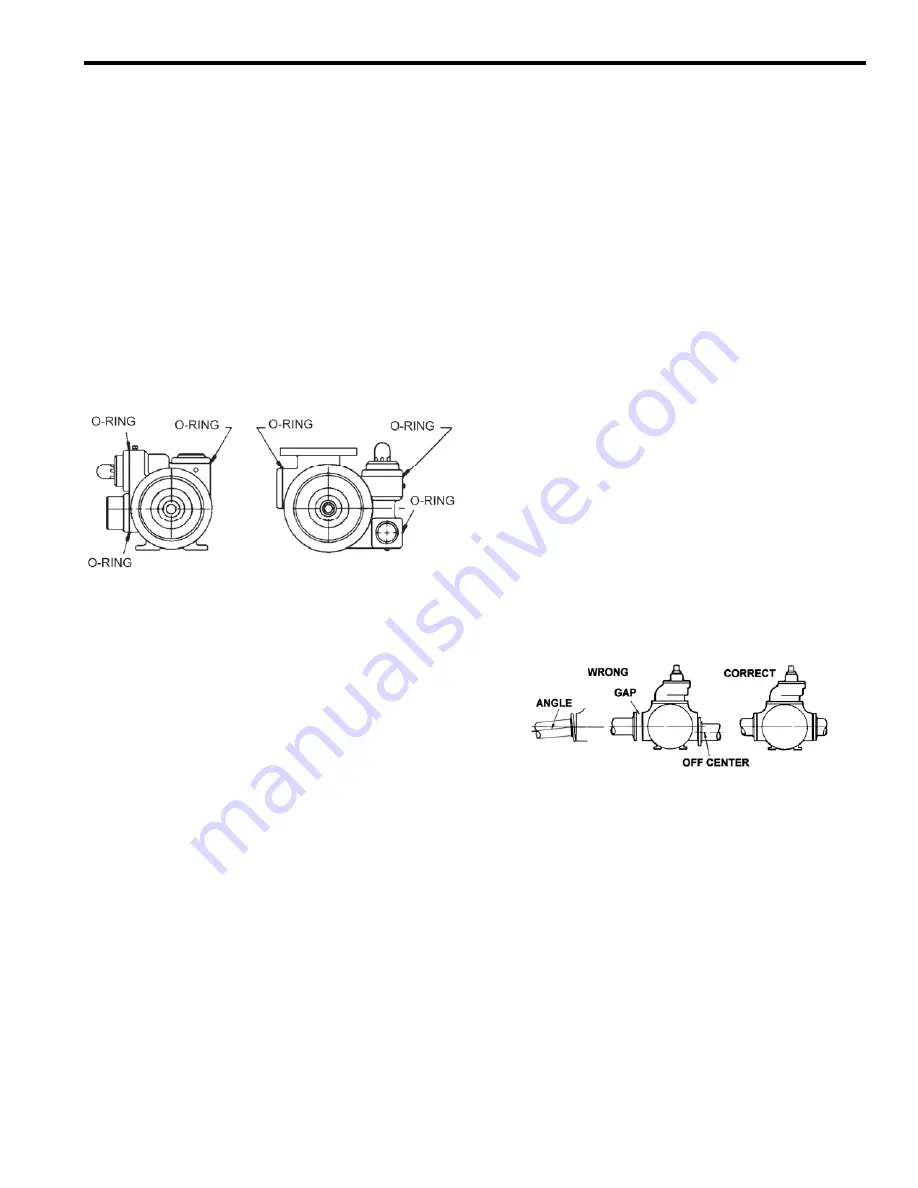

WELDED CONNECTIONS

NOTICE:

Pumps with welded connections contain three non-

metallic o-ring seals that will be damaged if welding is

done with these o-rings installed.

Prior to welding the piping, remove the O-rings from under the

inlet flange, outlet flange and relief valve cover as indicated in

Figure 1.

Reinstall the inlet and outlet flanges. Weld the piping to the

the inlet and outlet flanges. After the welding is complete,

reinstall the O-rings.

Figure 1

PRE-INSTALLATION CLEANING

NOTICE:

New pumps might contain residual test fluid and/or rust

inhibitor. If necessary, flush pump prior to use.

Foreign matter entering the pump WILL cause extensive

damage. The supply tank and intake piping MUST be

cleaned and flushed prior to pump installation and operation.

LOCATION AND PIPING

Pump life and performance will be significantly reduced when

installed in an improperly designed system. Before starting

the layout and installation of the piping system, review the

following:

1. Locate the pump as near as possible to the source of

supply to avoid excessive inlet pipe friction.

2. The inlet piping and fittings should be at least as large as

the intake port on the pump. It should slope downward to

the pump, and should not contain any upward loops.

Minimize the number of intake line fittings and eliminate

restrictions such as sharp bends; globe valves,

unnecessary elbows, and undersized strainers.

3. A strainer must be installed in the inlet line to protect the

pump from foreign matter. The strainer should be located

at least 24" (0.6m) from the pump, and have a net open

area of at least four times the area of the intake piping.

Strainers must be cleaned regularly to avoid pump

starvation.

4. The intake and discharge piping system must be free of

all leaks.

5. Expansion joints, placed at least 36" (0.9m) from the

pump, will compensate for expansion and contraction of

the pipes. Contact the flexible connector/hose

manufacturer for required maintenance/care and design

assistance in their use.

6.

ALL piping and fittings MUST be properly supported to

prevent any piping loads from being placed on the pump.

7. Check alignment of pipes to pump to avoid strains which

might later cause misalignment. See Figure 2. Unbolt

flanges or break union joints. Pipes should not spring

away or drop down. After pump has been in operation

for a week or two, completely recheck alignment.

Figure 2

8. Install pressure gauges in the NPT ports provided in the

pump casing to check pump performance at start up.

9. The use of a 1.5” or 2” vapor return line will speed up

delivery by preventing pressure build up at the receiving

tank and pressure reduction in the supply tank.

10. Keeping the liquefied gas systems full of liquid, even

when idle, will keep the O-rings from changing shape,

shrinking or super cooling. Evaporation of liquefied gas

leaves an abrasive powder on the surface which can

cause wear to the pump, meter, and seals.

Содержание CRL4B

Страница 15: ...701 C00 Page 15 16 NOTES...