23

disc on the

backing pad.

Fit the threaded

outer flange and

tighten as

explained in

‘Fitting the discs’.

HANDY HINTS

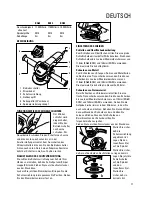

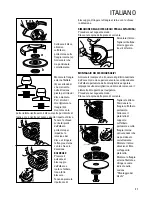

Hold your angle

grinder firmly with

one hand around

the side handle

and the other

around the body

of your angle

grinder.

• Always position the guard so that as much of the

exposed disc as possible is pointing away from you.

• Be prepared for a stream of sparks when the disc

touches the metal.

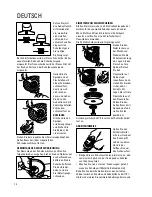

When grinding,

always maintain

the correct angle

between the disc

and the work

surface (15˚).

This increases the

removal capacity

of the disc and avoids unnecessary overloading.

ENGLISH

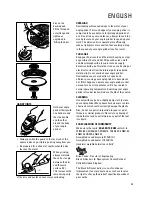

OVERLOAD

Overloading will cause damage to the motor of your

angle grinder. This can happen if your angle grinder is

subjected to heavy duty use for prolonged periods of

use. Do not in any circumstances, attempt to exert too

much pressure on your angle grinder to speed up your

work. The abrasive discs operate more efficiently

when a light pressure is exerted, thus avoiding a drop

in the speed of your angle grinder (see Tool care).

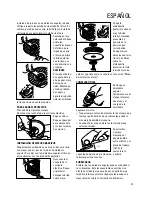

TOOL CARE

Keep guards, air vents and the motor housing as clear

as possible of dust and dirt. Wipe with a clean cloth

and blow through with a low-pressure air supply.

Excessive build-up of metal dust can cause tracking of

electrical current from the internal parts to exposed

metal parts. Do not overload your angle grinder.

Overloading causes a reduction in speed and

efficiency, causing your angle grinder to become too

hot. If this happens, operate your angle grinder under

no load for one or two minutes until it has cooled to

normal operating temperature. Switching your angle

grinder off under load will reduce the life of the switch.

CLEANING

Use only mild soap and a slightly damp cloth to clean

your angle grinder. Many household cleaners contain

chemicals which could seriously damage the plastic.

Also, do not use petrol, turpentine, lacquer or paint

thinners or similar products. Never let any liquid get

inside the tool and never immerse any part of the tool

into liquid.

EC DECLARATION OF CONFORMITY

We declare that units:

KG65, KG72, KG90

conform to

89/392/EEC, 89/336/EEC, EN55014, 73/23/EEC, EN55104,

EN50144, HD400, EN61000

A weighted sound pressure 97.7dB (A)

A weighted sound power 110.7dB (A)

Hand/arm weighted vibration <2.5m/s

2

Brian Cooke - Director of Engineering

Black & Decker Ltd, Spennymoor, County Durham

DL16 6JG United Kingdom

The Black & Decker policy is one of continuous

improvement to our product and as such we reserve

the right to change the product specification without

prior notice.

,,,,

,,,,

,,,,

,,,,

,,,,,

,,,,,

15

°

Содержание KG65

Страница 1: ... KG65 KG72 KG90 ...

Страница 62: ...4 97 1 ...