15

47

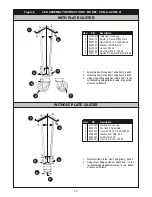

48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92

R3164A R3165A N5019A E8188A P9900A E8144A S0420A S6819A S6821A S6805A N7103A E8778A M1

114A

N3041A N5815A N8788A N3041A N1019A N8789A N8791A M1

115A

P1

144A

S6816A S6814A S0410A Q4033A E8125A E8159A S8159A U1451A M1326A P1900A U3149A U3103A U4197A E8790A E8064K S0430A L5090A N5007A M1360A E8779A S6804A Q2039A Q2016A M0120A R3002Y

Valve,

Combination

(Nat.)

Valve,

Combination

(L.P

.)

Nipple,

1/2"

X

1-1/8"

Steel

Pipe

Bracket,

Support

Clip

Jif

fy

1/2"

Bottom

Channel

Thrust

Bearing

Arm,

60

W

eldment

Arm,

40

W

eldment

Sprocket,

Door

(COM-G

Only)

Fitting,

Nut

S/S

Comp

1/4

T

ube

(Steam

Option

Only)

Bracket,

Mounting

(Steam

Option

Only)

Solenoid

V

alve,

1/8

X

1/8

(Steam

Option

Only)

Fitting

1/4

Comp

X

1/8

MPT

(Steam

Option

Only)

Fitting,1/4"

T

ube

Sleeve

S/S

Ferrule

(Steam

Option

Only)

Steam

T

ube

(Steam

Option

Only)

Fitting,

Fem

S/S

Comp1/4

T

ube

To

1/8

Pipe

(Steam

Option

Only)

Steam

Injection

Nozzle

(Steam

Option

Only)

Tube,

Supply

(Steam

Option

Only)

Tube,

V

alve

To

Oven

(Steam

Option

Only)

Solenoid

Coil

120/240V

, 17/12

W,

50/60Hz

(Steam

Option

Only)

Snap

In

Light

Assy

130V/15W

Eye

Hook,

Short

(COM-G

Only)

Eye

Hook,

Long

(COM-G

Only)

Turnbuckle,

1/4-20

(COM-G

Only)

Roll

Pin

.250

X

1.250

(COM-G

Only)

Bracket

W

eldment

Panel,

Right

Outer

Panel,

Insert

Control

BKI

Name

Plate

(Lg)

Switch,

4

Position

Rotary

Connector

, 1/2"

Flex

Straight

Label,

W

arning

Hot

Surface

(French)

Label,

W

arning,

Hot

Surface

Decal,

Caution

Disconnect

W

eldment,

W

all

T

ube

Mount

Adapter

, V

ent

(Direct

V

enting

Only)

Flange

Bearing

Burner Nipple,

1/2"

X

2-1/2"

Steel

Pipe,

Black

Transformer

, Class

2,

120/240V

-24V

, 40V

A

Bracket,

Mounting

(Potentiometer)

Chain,

Roller

#35

(COM-G

Only)

Nut,

Hex,

Left

Hand

1/4-20

S/S

(COM-G

Only)

Nut,

Hex,

1/4-20

S/S

(COM-G

Only)

Probe,

RT

D

Direct

V

ent

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34 35 36 37 38

39 40 41 42 43 44 45 46

E8189A E8138A M9208A S1

195A

E8160A S6810A M1

102A

E8170A E8178A E8177A E8176A E8156A E8193A M1332A M01

10A

E6895A M1352A P7200A P9600A P1

167A

M2138A M1

175A

M1335A M1

176A

M1049A S131

1A

21809210 21809220 E6825A E6827A U4198A S8768A S8019A T3044A T3043A E6865A L5091A M2140A R3180A R6756A R81

18A

R3161A E8187A E8143A M1323X N3010A N5024A N3009A

Baf

fle

Plate

Motor

Mount

Motor

1

15V

850/1725

RPM

Blower

Wheel

Panel,

Left

Outer

Cam,

Switch

Switch,

Door

Bottom

T

rim

Seal,

To

p

Seal,

Bottom

Door

Seal

(Between

Left

&

Right

Door)

Panel,

To

p

Outer

Control

Panel

Assy

.

Timer

, 60

Minute

Thermostat,

Fastron

G6

Bracket,

Buzzer

Switch,

Rocker

Terminal

Block

Pilot

Light

Green

(Power)

Light,

Indicator

250V

,

Amber

Ignition

Module

Timer

, Solid

State,

120

V

AC,

.5-60

Sec

(Steam

Option

Only)

Audio

Alarm

Potentiometer

(Steam

Option

Only)

Switch,

Push

Button

(2

Ea

-

Steam

Option

Only)

Knob Decal,

Blk/Red,

W

.O.

/

Steam

Decal,

Blk/Red,

W

/

Steam

Door

, 40

W/Window

Assy

Door

, 60

W/Window

Assy

Decal,

Leg

Catch,

Roller

Adjustable

Plate,

Striker

Support,

Wire

Rack

Rack,

Full

Size

Support,

Side

Rack

Burner

W/Ignitor

Bracket

Igniter

24V

Orifice

#48

Nat.

Only

Orifice

1.25mm

LP

Only

Manifold Carry

Over

, Pilot

Orifice

#71

(Nat)

Bracket

Manifold

Panel,

Front

Firebox

Flame

Sensor

Elbow

, 1/2"

X

90°

Nipple,

1/2"

X

8"

Union,

½"

1 1 1 1 1 1 1 1 1 1 2 1 1 1 1 1 1 1 1 1 1 1 1 1 1 3 1

1

1 1 1 1 1 2 5 8 1 1 4 4 1 1 1 1 1 3 1 2

Item

Part

#

Description

Quan

Item

Part

#

Description

Quan

4/05

Note:

When

ordering,

AL

W

A

YS

specify

Part

#,

Model

#,

Serial

#,V

oltage/Phase

&

type

of

Gas.

Page

3

of

4

1 1 3 1 2 6 4 1 1 2 2 1 1 2 2 1 1 1 1 1 1 2 2 2 2 2 1 1 1 1 1 4 1 1 1 1 1 1 3 1 1 1 2 2 2 1 1