◈

Information

This installation guide contains only simple information required for the installation of the

product. Refer to the User’s Manual in the CD that is shipped with the product for detailed

instructions for installation. The contents contained in the CD are as follows.

1. Manual: User’s Manual, Code Table, Control Commands, Software manuals

2. Driver: Windows Driver, OPOS, JPOS, CUPS(Linux, Mac), VCOM(USB, Ethernet)

3. SDK: UPOS SDK(iOS, Android)

4. Utility: Unified POS Utility, Net Configuration Tool, Android Utility, iOS Utility

We at Bixolon Co., Ltd. constantly strive to improve product functions and quality. To do

this, the specifications of our product and the contents of the manual may change without

prior notice.

◈

Components

SRP-380/382

Cable Cover

Roll Paper

Procuct Installation CD

Procuct Installation CD

Procuct Installation CD

CD

AC/DC Adaptor

Power Cord

Installation Guide

◈

Cable Connection

1. Turn off the printer and POS System(host computer).

2. Connect the power cord to adaptor, and connect the adapter to the power connector of the

printer.

3. Check the type interface located at the back of the printer(Serial, Dual Serial, Ethernet,

USB, Powered USB, Wireless LAN, Bluetooth) and connect proper cable.

4. Connect the drawer kick-out cable to the drawer kick-out connector located in the back of

the printer.

※

Do not use an adapter that was not supplied with the printer.

◈

Installing Paper Roll

1. Press the Cover-Open button to open the cover.

2. Insert new roll paper in the correct direction.

3. Pull the paper out slightly and close the cover.

※

Note

Hold down the center of the cover firmly when

closing the cover so that the paper maintains close

contact with the roller.

Printing quality may not be optimum if

recommended paper is not used.

(Refer to the User's Manual.)

◈

Paper Jam

(Refer to 1-8 in User’s Manual)

1. Turn the printer off and on, open the cover, and remove the paper.

2. If the cover cannot be opened, turn off the printer, separate the cover-cutter, and try to turn

the auto cutter knob to open the cover.

◈

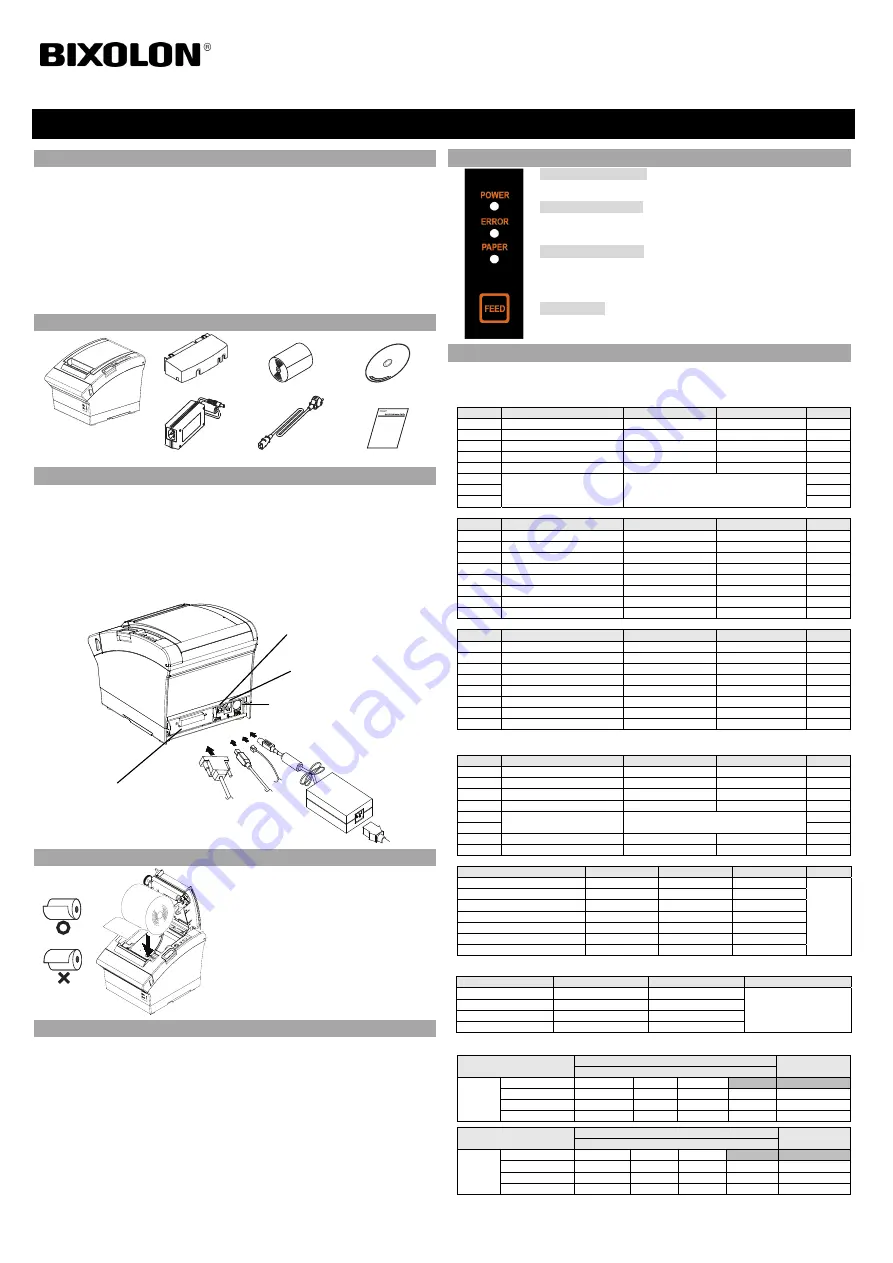

Using Control Panel

•

Power (Indicator Lamp)

Green light will be on when power is supplied to printer.

•

Error (Indicator Lamp)

Red light will be on in various error conditions such as out of paper,

cover open, etc.

•

Paper (Indicator Lamp)

Red light will be on when there is no paper or paper almost runs out. If

this light keeps blinking, it means that the printer is in self-test standby

state or waiting for macro execution.

•

Feed (Button)

Press this button to feed the paper out. Hold down this button to feed

out the paper continuously.

◈

Setting DIP Switches

DIP switch settings should be changed when the printer power is turned off. Any changes made

while printer power is on are not recognized.

1. DIP Switch 1

• Serial

/ Dual Serial Interface Settings

Switch

Function

ON

OFF

Default

1-1

Auto Line Feed

Enabled

Disabled

OFF

1-2 Flow

Control XON/XOFF DTR/DSR

OFF

1-3 Data

Length

7-bit

8-bit OFF

1-4 Parity

Check

Yes

No OFF

1-5 Parity

Selection

EVEN

ODD OFF

1-6

Baud Rate Selection (bps)

Refer to the following Table 1

OFF

1-7

ON

1-8

OFF

•

USB / Ethernet / Wireless LAN / Powered USB interface settings

Switch

Function

ON

OFF

Default

1-1

Auto Line Feed

Enabled

Disabled

OFF

1-2 Reserved

-

- OFF

1-3 Reserved

-

- OFF

1-4 Reserved

-

- OFF

1-5 Reserved

-

- OFF

1-6 Reserved

-

- OFF

1-7 Reserved

-

- ON

1-8 Reserved

-

- OFF

• Bluetooth Interface settings

Switch

Function

ON

OFF

Default

1-1

Auto Line Feed

Enabled

Disabled

OFF

1-2 Reserved

-

- OFF

1-3 SSP

Mode

Enabled Disabled

OFF

1-4 Reserved

-

- OFF

1-5 Reserved

-

- OFF

1-6 Reserved

-

- OFF

1-7 Reserved

-

- ON

1-8 Reserved

-

- OFF

2. DIP Switch 2

• All Interface Settings

Switch

Function

ON

OFF

Default

2-1 Reserved

-

- OFF

2-2 Reserved

-

- OFF

2-3 Internal

Bell

Control

Disabled

Enabled OFF

2-4

Auto Cutter Selection Disabled Enabled

OFF

2-5

Printing Density

Refer to the following Table 2

OFF

2-6

OFF

2-7

Near End Sensor Control

Disabled

Enabled

OFF

2-8

Auto External Buzz

Enabled

Disabled

OFF

• Table 1 – Baud rate(bps) selection

Transmission Speed

1-6

1-7

1-8

Default

2400 ON

OFF

OFF

9600

4800 ON

OFF

ON

9600 OFF

ON

OFF

19200 OFF

OFF

OFF

38400 OFF

ON

ON

57600 OFF

OFF

ON

115200 ON

ON

ON

* Please set up 9,600bps for baud rate of the dual serial interface.

• Table 2 – Printing density selection

Printing density

2-5

2-6

Default

Level 1

OFF

OFF

- Level 1 is Default

- Level 4 is Darkest

Level 2

ON

OFF

Level 3

OFF

ON

Level 4

ON

ON

※

Print Density

The print density can be set to one of sixteen different levels through virtual memory switches.

Dip Switch

Density

Density Level

Light Dark

Speed

4(High Speed)

4

Level 1

3

8

Level

2

2

12

Level

3

1(Low Speed)

16

Level 4

Memory Switch

Density

Density Level

Light Dark

Speed

4(High Speed)

1

2

3

4

Level 1

3 5

6

7

8

Level

2

2 9

10

11

12

Level

3

1(Low Speed)

12

13

14

16

Level 4

* Choose Unified Utility or Self-Test mode to set the print density using the VMSM(Virtual Memory Switch

Management).

Printer Installation Guide

KN04-00104A (Rev.1.1)

THERMAL PRINTER SRP-380/382

Power Cord

Interface Cable

(Serial/Dual Serial/Ethernet/

Powered USB/Wireless LAN/Bluetooth)

Adaptor

Drawer Kick-out

connector

Power

Connector

Interface Connector

USB

Cable

Drawer

Kick-out

Cable

USB

connector