3

INJECTION HAZARD

1. The Sprayer pumps coatings at high pressure (2500 PSI/173

Bar). If you spray yourself or anyone else at close range, the

stream of material can puncture the skin and cause great

harm (possible amputation).

2. NEVER point the spray gun at yourself or anyone else.

The tip guard provides some protection against injection

injuries, but it is mainly a warning device. NEVER remove

the tip guard. NEVER point the spray gun at your hands,

fingers, or body. ALWAYS keep the spray gun trigger

safety catch locked in the OFF position when not in use.

3. DO NOT cover the tip guard and attempt to “blow back”

fluid. This is not an air sprayer.

4. If injury occurs, see your doctor immediately! DO NOT

TREAT THIS AS A SIMPLE CUT. Inform your doctor

specifically of what fluid was injected.

AVOID STATIC SPARKING

Static electricity charge builds up by high velocity liquid flow-

ing through a hose during flushing, cleaning, or spraying oper-

ations. Proper grounding of the airless system safely dissipates

this charge.

All high pressure airless systems must be grounded to avoid

dangerous static sparking, explosion, or fire when spraying or

flushing with flammable liquids.

• Use Binks NO-WIRE conductive hose in all airless spraying

operations. Be sure the gun and hose have continuity. Check

continuity weekly with ohmmeter. Overall (end to end)

resistance of unpressurized hose must not exceed 29 megohm

(max.) for any coupled length or combination of hose lengths.

• Make sure the airless pump is grounded. NEVER operate the

unit when it is on a non-grounded platform. Electric airless

units are grounded through the grounding prong on the plug.

The electric cord or receptacle must be grounded. DO NOT

alter or remove grounding prong.

• When flushing or cleaning with a combustible solvent,

always use an open metallic container for receiving the

waste solvent. Ground the solvent receptacle.

• Bond the spray gun to the waste container with a grounding

wire. Be sure there is good metal to metal contact.

• ALWAYS remove spray tip when flushing the airless system.

Operate the pump at the lowest possible pressure.

GENERAL WARNINGS

1. NEVER leave a pressurized sprayer unattended.

2. DO NOT use fluids, coatings, or chemicals that are not

compatible with nylon hoses.

3. Periodically inspect all hoses for leaks and/or abrasions and

tighten all connections before use. DO NOT ATTEMPT

TO REPAIR a defective hose. REPLACE it with another

conductive hose.

4. Follow all warnings and precautions of the coating and

solvent manufacturers.

5. ALWAYS relieve pressure in the system by turning bypass

valve to BYPASS or triggering spray gun before

disassembly of any component parts.

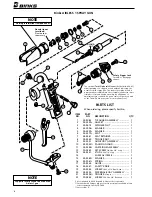

REPLACEMENT PARTS

The airless sprayer is designed to use authorized parts only.

When using this pump with parts that do not comply with the

minimum specifications and safety devices of Binks, the user

assumes all risks and liabilities.

WARNING

HIGH PRESSURE CAN CAUSE SERIOUS INJURY IF EQUIPMENT IS INSTALLED OR USED INCORRECTLY—

READ, UNDERSTAND, AND OBSERVE

ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL.

OPERATE EQUIPMENT ONLY AFTER ALL INSTRUCTIONS ARE CLEARLY UNDERSTOOD.

!