4

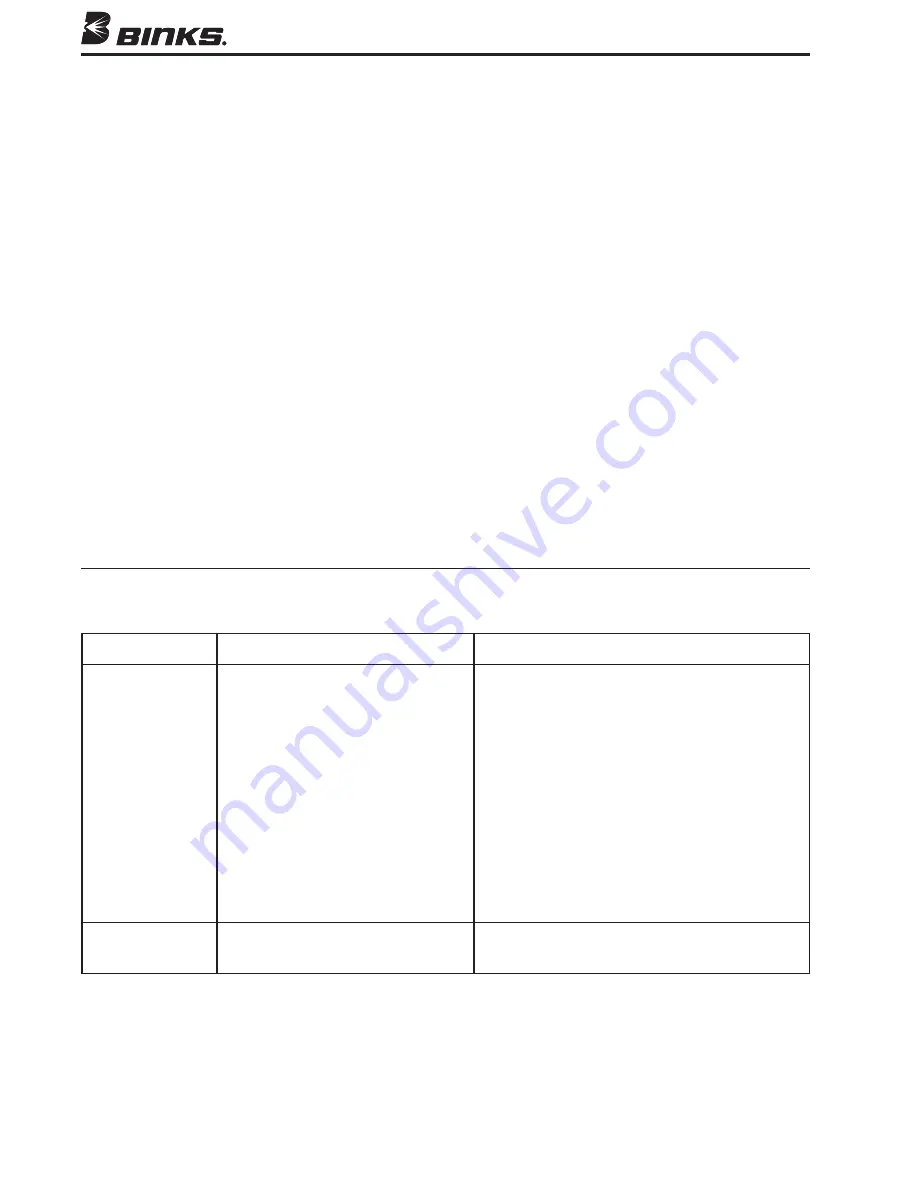

AIR MOTOR DRIVE SERVICE CHECKS

OPERATION AND MAINTENANCE

CONDITION

CAUSE

CORRECTION

1. Air motor needs lubrication or

cleaning.

2. Motor vanes need replacing or

contaminants present in motor

chamber, Figure 2.

3. Low oil level in gear box, Figure 3.

4. Gear and shaft assembly (58) and/

or worm gear (65) worn, Figure 3.

5. Air motor bearing (40 or 51) worn,

Figure 2.

Air motor

sluggish or

inefficient

Oil leakage

from gear box.

1. Seal (62, Figure 3) worn.

1. Lubricate (see "Air Motor Lubrication" section).

Disassemble and clean per parts replacement

instructions.

2. Disassemble, clean motor per parts replace-

ment instructions. Replace worn vanes.

3. Add oil per lubrication instructions.

4. Replace worn parts per parts replacement

instructions.

5. Replace bearings per parts replacement

instructions.

1. Replace seal per parts replacement

instructions.

Always install new gaskets (45) when reassembling air

motor.

Assemble the end plates to the body using an arbor press

with a pusher acting on both races of the bearing while

rigidly supporting the opposite (drive) end of the shaft.

Gear Box (refer fo figure 3, page 7)

1. Remove oil fill plug (60) or cover plate (56) and drain

gear box lubricant.

2. Remove set screws (63) and remove gear box from air

motor.

3. Disassembly gear box per exploded view, Figure 3.

Discard gaskets (59 and 64). Do not remove oil seal

(62) unless leakage or seal damage is indicated.

4. If oil seal (62) was removed, inspect seal seating bore

in housing (61). Remove any burrs or contaminants

from seal seating bore. Burrs or contaminants could

distort new oil seal during installation.

5. Inspect gear and shaft assembly (58) for wear grooves,

burrs, or contamination of seal seating area. If seal

seating area is damaged, shaft must be repaired or

replaced.

6. Inspect all other parts for wear spots, chipping, or other

damage. Replace damaged or worn parts.

7. If oil seal (62) is being replaced, inspect new seal for

damage before installing. Use arbor press to install

seal. Press fixture diameter must be close fit with gear

box bore diameter to avoid damage to seal. Install with

inner casing and sealing lip toward bottom of bore.

Drive seal squarely into bore to avoid warping. Oil seal

is recessed 3/32 inch from bottom of housing (61)

when properly installed.

8. Reassemble gear box per exploded view. Install new

gaskets (59 and 64). Just prior to assembling gear box

with air motor, apply a small dab of thread locking

compound (53) to threads of setscrews (63). Connect

motor and gear box and torque set screws (63) to 60

inch-pounds (6.8 N-m), minimum. Refill gear box per

gear box lubrication instructions.