CLEANING THE GUN—WHEN

USED WITH PRESSURE TANK:

Shut off the air supply to the Pressure

Tank and release the pressure in the tank.

Hold a piece of cloth over the gun nozzle

and pull the trigger, the air will back up

through the fluid nozzle and force the

fluid out of the hose and into the tank.

Remove paint from tank, clean tank and

put enough compatible solvent into the

tank to clean the hose and gun thoroughly.

Spray this through the gun until it is clean,

then blow out the fluid hose to dry it and

remove all traces of materials by attaching

it to the air line.

WHEN USED WITH A CUP:

A compatible solvent should be siphoned

through gun by inserting tube from siphon

cup in an open container of solvent.

Trigger gun intermittently to thoroughly

flush passageways and internal parts.

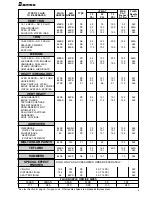

HOW TO USE THE CHART

A.MATERIAL TO BE SPRAYED

Select the type of fluid you want to

spray or a fluid which has the same

characteristics as one of those listed.

B.METHOD OF FEEDING MATERIAL

TO THE GUN

Fluid Nozzle—Consider the speed of

application and the viscosity of the fluid

to be sprayed. Refer to the Fluid Nozzle

Orifice Size Chart, below.

Air Nozzle—Choice is determined by

the type of fluid to be sprayed and the

volume of air available for the gun.

• External Mix Nozzles, which are

generally used, accomplish atomiza-

tion outside the nozzle. Spray patterns

are adjustable from round to fan

with all intermediate patterns.

(Designated by the letter “E”).

• Siphon Type External Mix Nozzles,

designated by the letter “S”, will

siphon the material from a cup.

Used generally for refinished and

touch-up work which does not

require large quantities of paint.

• Pressure Type External Mix Nozzles,

designated by the letter “P”, require

pressure to feed the material to the

nozzle. A pressure cup, pressure

tank or pump is necessary. Used for

production work and where large

quantities of fluid are handled. This

type of nozzle has a greater range of

fluid flow and does not limit the size

of the paint container.

• Internal Mix Nozzles mix the air and

fluid within the air nozzle. The spray

pattern is determined by the shape of

the nozzle and cannot be changed.

Internal mix nozzles require less air

and produce slightly less fog. Pressure

equipment must be used with this type

of nozzle. Recommended for mainte-

nence spraying of heavy materials

where a fine finish is not required.

(Designated by the letter “I”).

C. VOLUME OF AIR (CFM REQUIRED)

The cubic feet per minute (CFM) listed

at 30, 50 and 70 PSI is the actual air

used by the air nozzle. increase of pres-

sure subsequently increases volume of

air required by air nozzle, or vice versa.

Assume that a compressor will produce

3-5 CFM per horsepower.

It is extremely poor practice to mount the

oil and water extractor on or even near

the compressor unit. The temperature of

the air is greatly increased as it passes

through the compressor and this com-

pressed air must be cooled before the

moisture in it will condense. if the air

from the compressor is still warm when

it passes through the oil and water extrac-

tor, moisture will not be effectively

removed, but will remain in suspension.

Then, when the air cools in the hoe beyond

the extractor, the moisture will condense

into drops of water and cause trouble.

Air lines must be properly drained.

Pitch all air lines back towards the

compressor so that condensed moisture

will flow back into the air receiver where

it can be removed by opening a drain.

Every low point on an air line acts as a

water trap. Such points should be fitted

with an easily accessible drain.

See diagram above.

PITCH PIPE AWAY

FROM AIR RECEIVER

COMPRESSOR

UNIT

OIL AND WATER

EXTRACTOR

INSTALL

DRAIN

AT EACH

LOW

POINT

DRAIN

DRAIN

25 FEET OR MORE

Oil and Water Extractor should be at least 25 ft. from the compressor. Further if possible.

PIPE SIZE, I.D. (inches)

Length of Pipe (feet)

50

100

150

200

1/2"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

3/4"

1"

1"

1"

1"

1"

1"

1"

1"

1"

1"

1"

1"

1-1/4" 1-1/4"

Air Flow

CFM

10

20

30

40

50

70

2

NOTE

The greater the air consumption, the

faster the fluid may be applied or the

finer a given amount of fluid can be

atomized.