BIJUR DELIMON INTERNATIONAL

(919) 465 4448

LOCAL

(800) 631 0168

TOLL-FREE

(919) 465 0516

FAX

WWW.BIJURDELIMON.COM

2250 Perimeter Park Dr., Suite 120

Morrisville, NC 27560

36734 • R0

04/17

2

Maintenance

Check oil level daily and refill reservoir when required. Check the system periodically for loose or

broken tubing, worn hoses, loose fittings and connections. Replace filter group annually.

Filter Replacement

125 micron porous metal filter on pump inlet, which should be inspected periodically and replaced

as required (recommended annually). For replacement of filter element, specify filter group part

#S-222.

Motor Replacement

1. Disconnect the electrical supply from the motor, disconnect system tubing and remove lubricator

unit from the oil reservoir by opening the four M5 screws that are connecting the pump to the top

plate.

2. Turn the lubricator unit upside down.

3. Remove the two M4 SHC screws holding the gear pump to the downspout and remove the gear

pump and inlet gear pump adapter. Remove the three #8-32 socket cap screws holding the

downspout onto the motor and lift the downspout clear from the motor. Carefully remove the motor

driveshaft and coupling.

4. Replace the motor and carefully re-assemble the motor driveshaft / motor coupling onto the new

motor shaft. The motor coupling must be equally spaced between the motor driveshaft and the motor

shaft.

5. Re- assemble the downspout onto the motor by carefully lining up the three holes and inserting

and tightening the three #8-32 socket cap screws.

6. Re-assemble the gear pump to the downspout, ensuring that the shaft of the gear pump meshes

with the motor driveshaft. Place the inlet gear pump adaptor and O ring onto the gear pump and then

insert the two M4 SHC screws to hold in place.

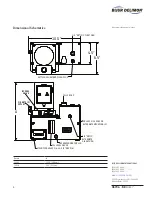

Motor Wiring - 115vac Single Phase

MOTOR

LINE

1

4

0

8

LINE

CAP