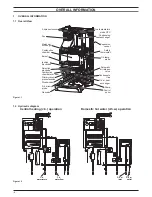

Wall hung, fanflue, roomsealed, high efficiency gas boiler

Service manual

Riva Plus HE

Models

G.C. Appl. No.

M296.24SM/C

47-583-24

CoMbi boilER

M296.28SM/C

47-583-25

CoMbi boilER

leave this manual adjacent to the gas meter

Warning:

Service / repairs must be carried out, only by a qualified Gas Safety

Registered Engineer, who will be responsible for the current Regulations for

gas appliances.

Note:

After servicing, complete the relevant Service interval Record section of the

benchmark Checklist of the user and installation manual.

Содержание Riva Plus HE M296.24SM/C

Страница 2: ......

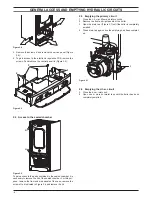

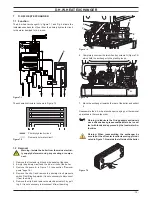

Страница 45: ...45 Short spare parts list 1 2 6 4 5 7 3 8 14 12 18 20 21 23 25 26 13 15 24 16 17 9 10 11 9 19 27 22 Figure 22 1...

Страница 46: ...46 NOTE...

Страница 47: ......