RIVA ADVANCE COMBI MANUAL

6

1

17. Annual Maintenance Cont.

17.13 Water inhibitor concentration:

Where chemical products are used the level of water treatment should be checked on an

annual basis and re treated after full or partial drain down.

A conductivity meter can be used to check the correct concentration of inhibitor in the heating

water. See the section 15.1 of this handbook.

17.14 Checking the condensate drain pipe:

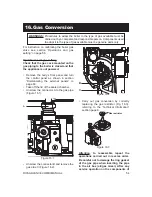

The condensate drain

system should be

checked yearly during a service.

C

heck:

•

That no solid deposits have formed, if so

remove them.

•

Remove the forks E and remove the

condensate trap A moving it downwards

(Fig. 17.8).

Figure 17.8

A

D

E

17.16 Setting the boiler chimney sweep function:

With the boiler set in chimney sweep

mode, it is possible to exclude some boiler

automatic functions making check and

control operations easier.

•

Position the control panel knobs as shown

in Figure 17.9.

Figure 17.9

8

7

6

•

Electrically power the boiler, the following

will appear on the LCD display.

Figure 17.10

•

To enter Chimney cleaning mode, enter

programming by pressing the reset

button 6 in Figure 17.9 for 15 seconds

That the condensate drain piping is not

clogged

, if so clear the clog.

Unscrew the plug D to clean inside the pipe.

Removal

•

17.15 Checking Low Water Cutoff

If a low water cutoff is installed on a system, it’s function should be checked as part of

the yearly service. Refer to the low water cutoff manufacturers instructions

f

or

maintenance and testing.

•

Содержание Riva Advance Combi

Страница 70: ...RIVA ADVANCE COMBI MANUAL 70 NOTE...

Страница 71: ...71 RIVA ADVANCE COMBI MANUAL NOTE...

Страница 72: ...1796220630 17962 2063 0 2712 76A4 USA 06 07 2012 N...