11

Installation

6006047_0 – 02.09.2021

EN

y

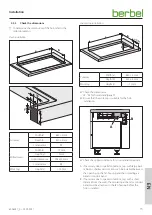

The device must remain accessible at all times for

maintenance work (e. g. with a removable rear panel or

service cover). The space must be sufficiently large to

allow for removal of the recirculated air filter.

y

During recirculated air mode sufficiently large ventilation

slots must be available for the ventilation.

y

The air flowing out must be able to dissipate unimpeded.

y

If necessary for the installation, only use suitable hob

protection grates or hob covers.

☞

Please consult your dealer or customer services.

Country-specific, legal provisions must be observed.

3.3

Requirements for individual operating modes

Depending on the operating mode, further accessories are

required:

3.3.1

Requirements for recirculated air mode

y

Recirculating air kit DL BUF or DL BUR.

y

Recirculated air fan on the fan outlet.

y

Minimum size of the fan outlet opening in the lower

cabinet 2 x 250 cm

2

.

y

Filter filling freely accessible for changing.

y

The air escaping from the recirculation filter must be

fed out of the cabinet in a closed system (“guided

recirculating air”).

It is only possible to dispense with a guided recirculating

air system if cabinet or structural building damage due

to moisture (e.g. caused by condensate) can be fully

excluded.

y

The installation variant with recirculated air filter permalyt

(recirculating air kit DL BUR) requires an additional 230 V

socket.

3.3.2

Requirements for extracted air mode

y

Exhaust air kit DL.

y

Exhaust air ducting at the fan outlet.

D

“3.4 Requirements for the exhaust air ducting

(only for extracted air mode)” (page 11).

y

Diameter of the exhaust air ducting at least 150 mm

(corresponds to a surface area of approx. 177 cm

2

).

y

Adequate fresh air supply is assured through the

installation of the necessary accessories.

y

Window contact switch BKA DL.

y

Wall box.

3.4

Requirements for the exhaust air ducting

(only for extracted air mode)

D

WARNING!

Fire hazard and asphyxiation hazard due to improper

installation!

When using the exhaust air ducting with other devices

or when connecting an active exhaust air channel (e.g.

chimney), gases or smoke can be drawn into the room.

☞

Make sure that the requirements for the exhaust air

ducting are complied with.

y

The exhaust air ducting is used exclusively by this device.

y

The exhaust air ducting is made of non-combustible

material in accordance with DIN 4102 class 1.

y

When using a chimney as the exhaust air duct:

y

The chimney must not be used by other devices.

y

The extracted air must be introduced into the

chimney using a 90° bend pointing upwards.

y

Approval by a master chimney sweep.

y

When routing the exhaust air ducting through the roof or

the outside wall:

y

The cross-section must not be smaller than that of the

fan outlet.

y

Installation of condensed water collector in the

exhaust air ducting in order to prevent water damage

inside the device. The condensed water collector must

be adequately dimensioned.

The cross-section, length, type and course of the exhaust

pipe affect the extraction efficiency. Changing the direction

of the air too severely leads to a loss of performance and to

noise.

To optimise the device performance:

y

Keep the exhaust air ducting as short as possible (no

longer than 4 m) and route it directly to the outside.

y

The stipulated cross-section of the exhaust air ducting is

complied with.

D

“3.3 Requirements for individual operating modes”

(page 11).

y

Exclusive use of ducts and bends with smooth inner

surfaces.

In order to avoid turbulence or backpressure in the

transported air - do not use:

y

Spiral hoses.

y

Flexible tubes.

y

Flat deflection pieces.

y

Sharp-edged exhaust air channels.

The exhaust air ducting must be in place before installing

the device.

Содержание Downline Infinity BKA 90 DLI

Страница 44: ...6006047_0 02 09 2021 ...