9

General

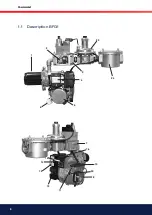

1.1.1 Components BFG1

1.

Blast tube

2.

Gas pressure switch

3.

Connection multiblock

4.

Ignition transformer

5.

Motor

6.

Capacitor

7.

Multiblock

8.

Air pressure switch

9.

10. Air intake

11. Air regulation

12. Electric connection

13. Gas burner control

14. Reset button

15. Nozzle assembly adjustment

16. Screw for division of burner in front and rear part

17. Nozzle assembly

18. Brake plate

19. Ignition electrode

20.

21. Nozzle

22. Air fl ow indicator (indicates the air setting)

23. Pressure regulator

24. Filter

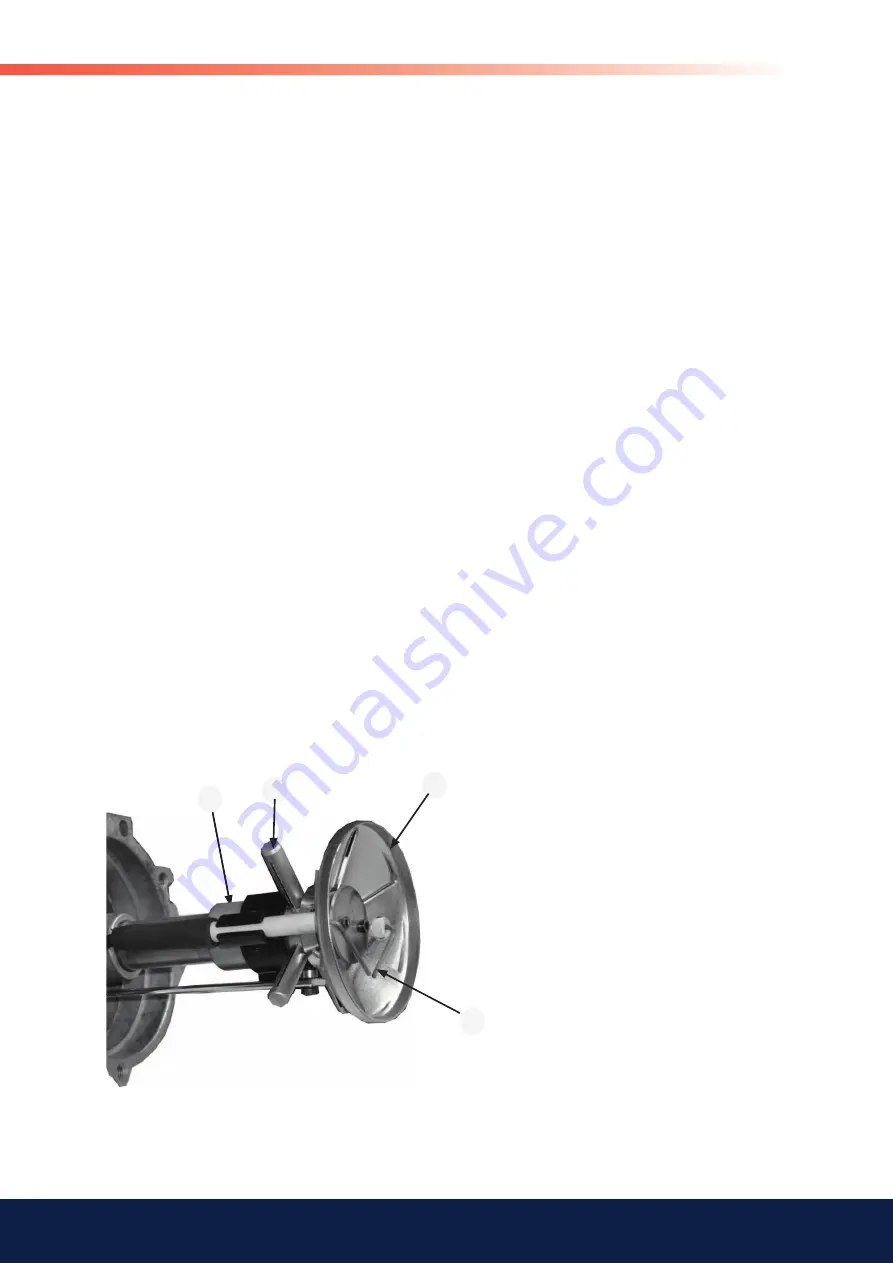

18

19

17

21

Содержание BFG1

Страница 2: ......

Страница 8: ...8 General 1 1 Description BFG1 7 8 10 11 12 13 14 15 16 22 1 2 3 4 5 6 24 23...

Страница 11: ...11 General 7 8 10 9 1 2 3 5 6 12 4 2 1 Description STG 23 24 16...

Страница 20: ...20 General 4 ELECTRIC EQUIPMENT LME 4 1 Wiring diagram Alt 1 Enl DIN 4791 Alt 2 Alt 3...

Страница 24: ...24 General...

Страница 25: ...25 General...

Страница 26: ...26 General...

Страница 27: ......

Страница 28: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...