9

4.

If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5.

Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6.

Never exceed manufacturer’s recommended

pressures.

7.

Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8.

Use only genuine Bendix

®

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9.

Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

REMOVING EC-14

™

CONTROLLER ASSEMBLY

Locate the EC-14

™

controller on the trailer and determine if

it is mounted on a modulator (e.g. M-12

™

modulator) or is

remote mounted to a trailer frame member using a bracket.

Use the appropriate removal procedure below.

Removing the EC-14

™

Controller and M-12

™

Modulator:

1. Identify and remove all air lines connected to the

M-12

™

modulator.

2. Disconnect the electrical connector from the EC-14

™

controller.

3. Note and mark the mounting position of the MC-14

™

modulator-controller assembly on the vehicle. Loosen,

remove and save the nuts on the mounting hardware

that attaches the MC-14

™

modulator controller bracket

to the vehicle. Remove the MC-14

™

modulator controller

assembly from the vehicle.

4. Remove as much contamination as possible from the

exterior of the assembly making sure to keep the

contamination away from the open ports.

5. Note and mark the position of the EC-14

™

controller

relative to the M-12

™

modulator. Remove and retain the

four hex cap screws that secure the EC-14

™

controller

to the M-12

™

modulator. Carefully separate the EC-14

™

controller from the M-12

™

modulator enough to expose

the wire harness that connects both units electrically.

Disconnect the wire harness by separating the four pin

connector at the EC-14

™

controller. Peel the gasket from

the EC-14

™

controller or M-12

™

modulator and retain for

reuse. Note: Use a new gasket if damaged during

removal or if a new gasket is immediately available.

INSTALLING THE EC-14

™

CONTROLLER

ASSEMBLY

1. After noting the positioning marks made prior to

disassembly, reconnect the M-12

™

modulator wire

harness to the EC-14

™

controller, position the gasket

on the EC-14

™

controller then secure the EC-14

™

controller to the M-12

™

modulator using the four cap

screws. Torque the cap screws to 50-80 Ibs. in.

2. Mount the assembled MC-14

™

modulator controller on

the vehicle and orient it in the position marked prior to

removal.

3. Reconnect all air lines.

4. Reconnect the electrical connector to the EC-14

™

controller.

5. Test the MC-14

™

modulator controller for operation and

air leakage prior to placing the vehicle in service.

6. Perform the “Initial Start up Procedure” in the

Troubleshooting section to assure proper antilock

system operation.

DIAGNOSING AND LOCATING A SYSTEM

PROBLEM

GENERAL

The EC-14

™

controller contains self test and diagnostic

circuitry that continuously checks for proper operation of

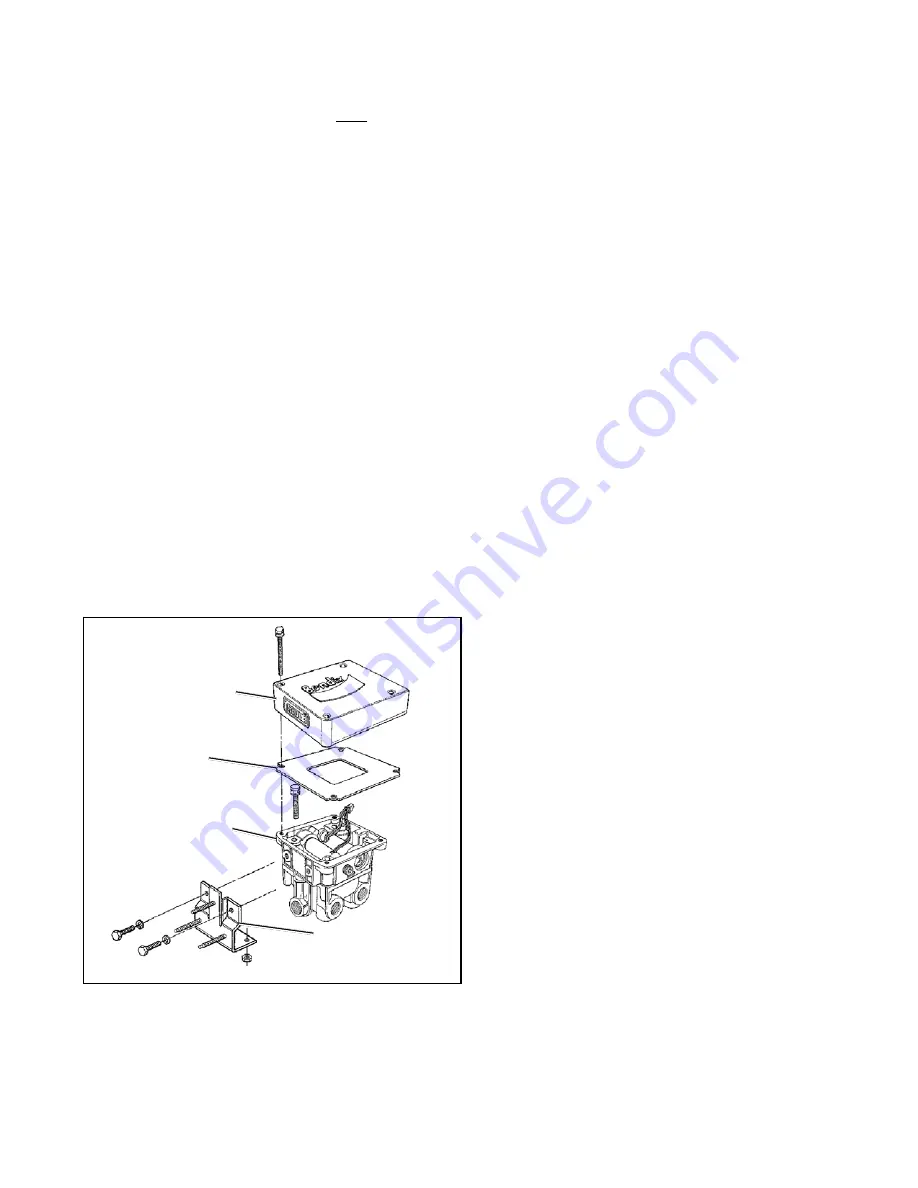

FIGURE 7 - MC-14

™

MODULATOR CONTROLLER

EC-14

™

CONTROLLER

GASKET

MOUNTING

BRACKET

M-12

™

MODULATOR

Содержание EC-14 ANTILOCK CONTROLLER

Страница 2: ...2 FIGURE 2 MC 14 ANTILOCK BRAKE SYSTEM...

Страница 8: ...8 FIGURE 6 MC 14 ANTILOCK WIRING SCHEMATIC...