6

5.

INSTALLATION

5.1

Location

The appropriate model BR323AL or BR323SS

should be chosen depending on the severity of

the environment. The BR323AL is housed in an

epoxy painted aluminium enclosure and the

BR323SS in a stainless steel enclosure suitable

for marine applications. Both provide IP66 and

NEMA Type 4X protection.

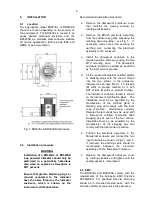

Fig 5 BR323AL & BR323SS dimensions

5.2

Installation procedure

WARNING

Installation of a BR323AL or BR323SS

loop powered indicator should only be

performed in a potentially hazardous

area when an explosive atmosphere is

NOT present.

Ensure that glands, blanking plugs or

conduit connected to the indicator

have the same thread as the indicator

enclosure, which is shown on the

instrument certification label.

Recommended installation procedure:

a.

Remove the flameproof enclosure cover

that contains the viewing window by

rotating anticlockwise.

b.

Remove the BR323 electronic assembly

from the enclosure by gently squeezing the

retaining clip and pulling – see Fig 1. If

necessary remove the screw securing the

earthing wire connecting the electronic

assmebly to the enclosure.

c. Install the flameproof enclosure in the

required position and secure using the two

M10 mounting slots. The flameproof

enclosure should be earthed as specified

by the local code of practice.

d.

Fit the required flameproof certified glands

or blanking plugs with the correct thread

into the two entries in the enclosure.

Instruments can have M20 x 1.5 threads

(M suffix on producr number) or ½ inch

NPT entries (N suffix on product number).

The instrument enclosure thread is shown

on the instrument certification label. The

installation must be as specified by the

manufacturer of the certified gland or

blanking plug and comply with the local

code of practice. Alternatively, correctly

threaded metal conduit may be used with

a flameproof certified compound filled

stopping box at each of the two entries.

Installation must be as specified by the

manufacturer of the stopping box and

comply with the local code of practice.

e. Position the electronic assembly in the

flameproof enclosure and connect the two

input terminals as shown in Figs 1 and 4.

If removed, the earthing cable should be

reconnected between the electronic

assembly and the flameproof enclosure.

f. Replace the flameproof enclosure cover

by rotating clockwise and tighten until the

sealing gasket is compressed.

5.3 EMC

The BR323AL and BR323SS comply with the

requirements of the European EMC Directive

89/336/EEC. For specified immunity all wiring

should be in screened twisted pairs, with the

screens earthed at one point in the safe area.