23

8.3 Servicing

ENSURE PLANT SAFETY BEFORE

STARTING MAINTENANCE

Live maintenance should only be

performed when there is no risk of a

flammable atmosphere being present,

and dust or water can not enter the

enclosure. De-energise the 4/20mA loop

and power to the optional backlight and

relay contacts before starting any

maintenance.

Before replacing control and terminal

covers ensure that the sealing gskets are

undamaged and are free from dirt and

foreign bodies.

To simplify servicing all BA354ND rate totaliser

use a common display assembly which may be

replaced on site. Depending upon the

accessories fitted, one spare display assembly

may be used to repair any BA354ND rate totaliser

which fails.

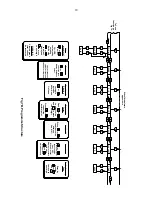

To replace the display assembly remove the

terminal cover by unscrewing the two 'A' screws

which will reveal two concealed 'D' screws.

Unscrew all four 'D' screws and carefully lift off the

front of the instrument as shown in Fig 4. The

instrument assembly is secured by four Pozi

headed screws which should be removed. If the

instrument is fitted with a backlight or alarms the

fly-leads connecting the accessory boards to the

terminals should be un-plugged. The replacement

display assembly may then be installed and the

enclosure reassembled.

If after replacement of the display assembly the

instrument still does not function, it is likely that the

fault is within the protection components on the

terminal assembly. Terminal assemblies may be

exchanged on-site providing the replacement

includes terminals for any accessories fitted to the

display assembly i.e. terminals for backlight and

alarms.

We recommend that faulty instruments and

instrument assemblies are returned to BEKA

associates or to our local agent for repair.

8.4 Routine maintenance

The mechanical condition of the instrument and

electrical calibration should be regularly checked.

The interval between inspections depends upon

environmental conditions. We recommend that

initially instrument calibration should be checked

annually.

8.5 Guarantee

Indicators which fail within the guarantee period

should be returned to BEKA associates or our local

agent. It is helpful if a brief description of the fault

symptoms is provided.

8.6 Customer comments

BEKA associates is always pleased to receive

comments from customers about our products and

services. All communications are acknowledged

and whenever possible, suggestions are

implemented.