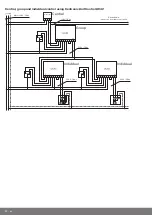

Disassembling the drive adapter with safety catch on the drive shaft

Disassembly with disassembly tool, Item no. 4930 300 606 0

Disassembly with long nose pliers

2.

1.

Mounting the drive in the tube

For profile tubes:

In the case of some drive adapters, tolerances of the groove widths in different bar-

rels can be offset by rotating the drive adapter into a different groove recess. These

groove recesses have different sizes and allow the drive to fit exactly.

Y

X

For round shafts:

Measure the lug of the thrust ring (X, Y). Then notch the tube on the motor side, so

the lug of the thrust ring can also be pushed into the shaft. There must be no play

between the lug of the thrust ring and the shaft.

-10 mm

To ensure secure torque transmission for round shafts, we recommend screwing the

drive adapter to the shaft (see the table below).

Attention! When drilling into the barrel, never drill near the tubular drive!

Size of drive

[mm]

Drive adapter

Torque

max. [Nm]

Fastening screws

(4 units)

dia. 35-dia. 45

All

Up to 50

Self-tapping screw

dia. 4.8 x 9.5 mm

We also recommend screwing the idler to the barrel.

8 - en

Содержание enocean R8-17

Страница 23: ...Declaration of conformity 23 en ...

Страница 24: ...Declaration of conformity 24 en ...

Страница 28: ......