Deleting the limit positions with a rotary switch or a locking button

The switching commands sequence must be carried out in quick succession.

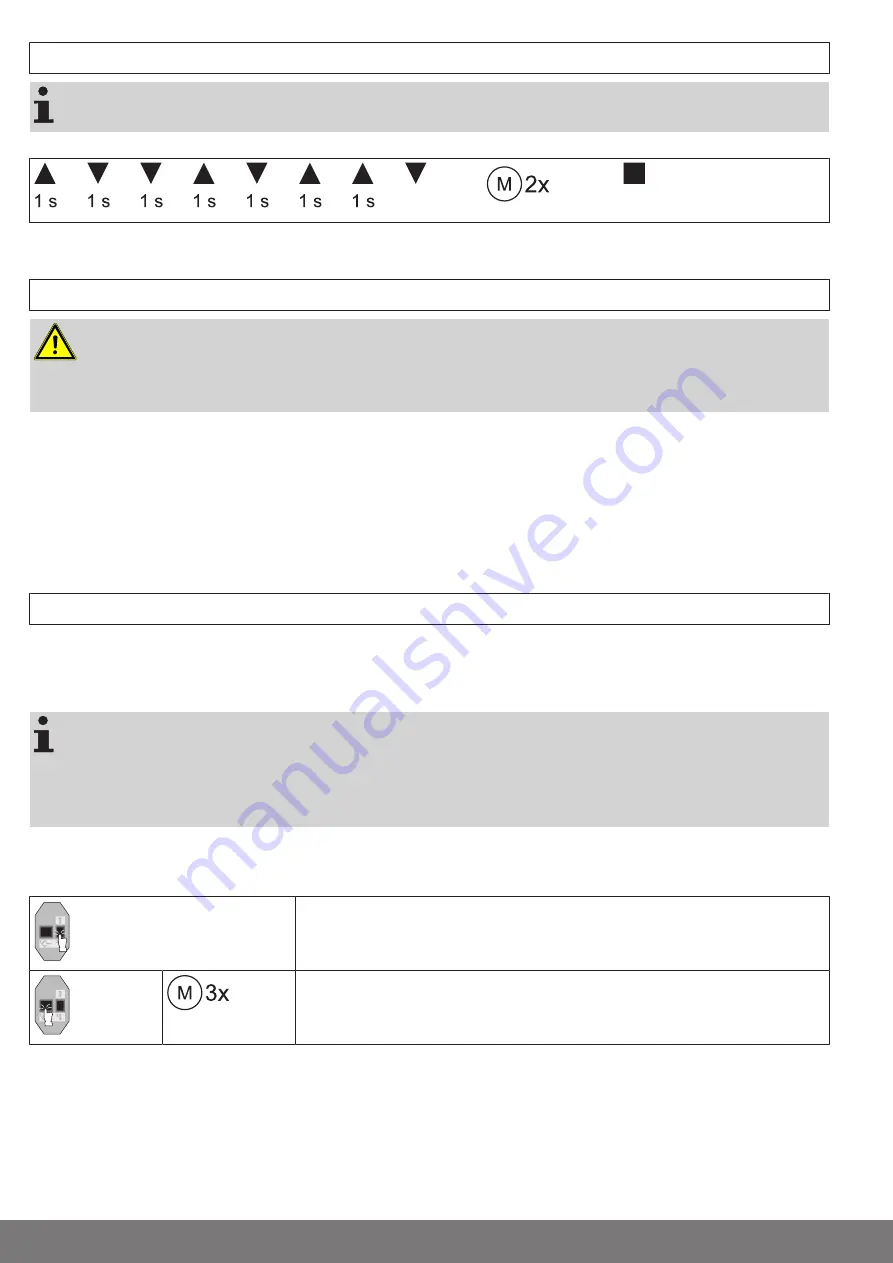

Carry out the following deletion sequence without interruption between the individual drive commands:

until

STOP

The tubular drive acknowledges.

Both limit positions are deleted.

Obstruction detection / Blockage detection

Caution

Use of the drive’s obstacle detection system as personal protection is not permitted. It has

been designed exclusively to protect the roller shutters or sun protection system from be-

ing damaged.

If the drive is correctly installed, it switches off when it detects obstructions or shutter faults.

The following are detected both when using attachment springs and when using anti-lifting devices:

In the DOWN direction (Obstruction detection)

A curtain jam when closing due to objects on the window sill or sticking of the lateral guide tracks.

In the UP direction (Blockage detection)

Extremely large increase in the load (e.g., frozen end strip on the window sill)

To avoid overly sudden deactivation during closing, the drive only responds to an obstruction one or two revolutions after the im-

pact.

Additional upper anti-freeze mechanism

The upper anti-freeze mechanism helps to prevent the roller shutter from freezing in the upper limit position, as the roller shutter

stops just before the upper stop. The distance from the upper stop is automatically cyclically checked and, if necessary, correc-

ted.

Both limit positions must be set before the anti-freeze mechanism can be activated.

The anti-freeze mechanism only works if a permanent stop is set at the upper limit position

of the roller shutter. The anti-freeze mechanism is not visible until the shading solution has

reached the upper stop from the lower limit position 3 times in succession.

When the limit positions are deleted with the programming unit, this set function is reset to

the factory setting.

This function is deactivated on delivery.

Activating/deactivating the upper anti-freeze mechanism

Open/close the shading solution to a point between the limit positions.

10s

Press the programming button on the programming unit for approx. 10 seconds.

►

The tubular drive confirms.

14 - en