Operating Manual for

FAN Press Screw Separator PSS 1.1-300

19

9

TEST FOR SEPARATION CAPABILITY

In order to test the separation capability of the medium supplied to the separator, you can perform a

simple suitability test. Take some of the medium intended for separation into your hand and try to press

it out. If the medium is a very fine-grained solid and seeps through your fingers during this test, it cannot

be mechanically separated without reducing the viscosity.

However, if liquid escapes through your fingers and solid matter remains in your hand when opened,

then this medium can be separated in the separator.

You can also perform this test with the effluent of the separator to determine whether further separation

in the separator is possible by using screens with lower gap widths. For example, if the first separator is

operated with a gap width of 0.75 mm, the effluent can be introduced to a separator with a gap width of

0.25 mm and so on.

To determine the possible dry matter content for your application using the separator, perform a screen

test, such as with a screen of gap width 0.50 mm. The dry matter content when using the separator will

always be higher than your test result since the solids are filtered by the solid cake, meaning that even

solids with a size smaller than 0.50 mm will be captured in the cake.

10

LIQUID CLEANING

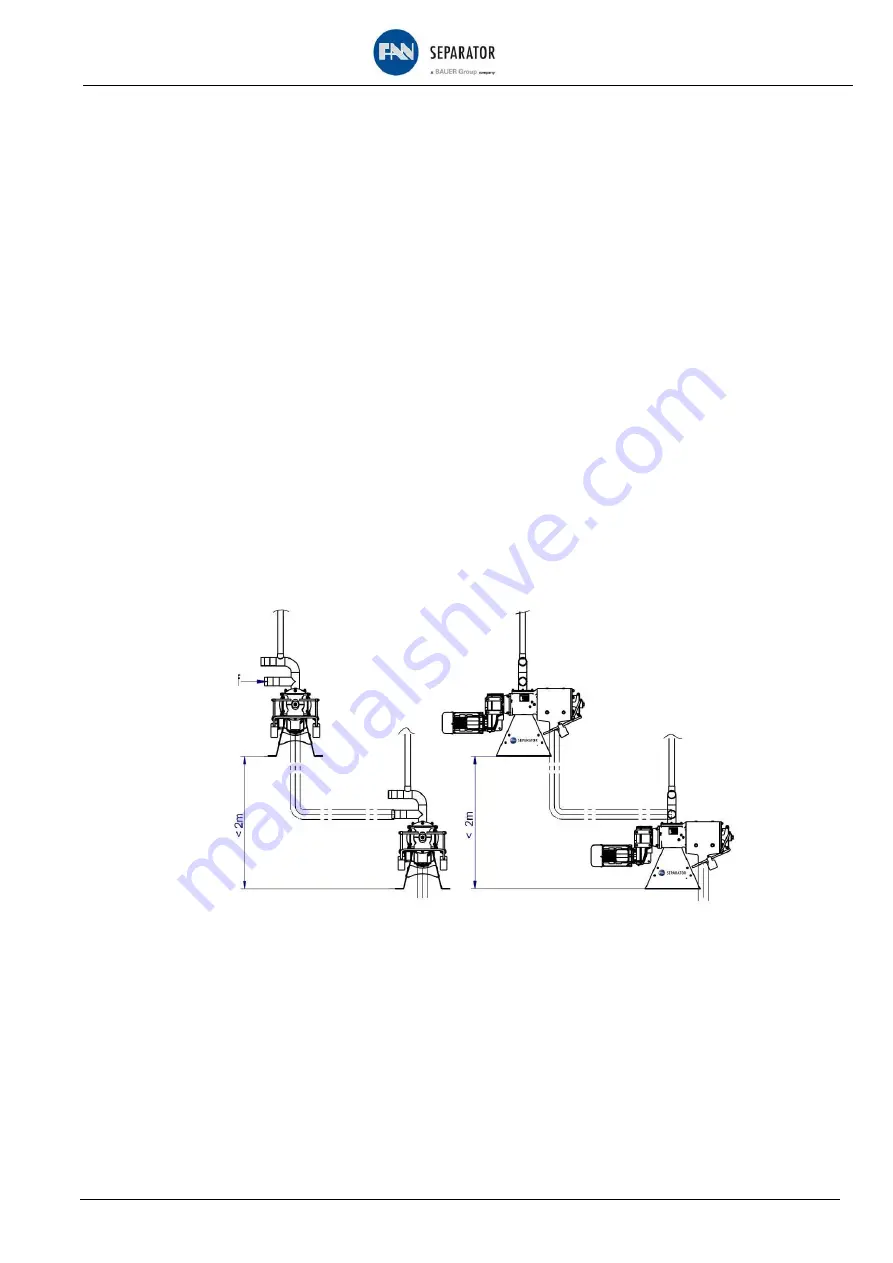

Fig. 10-1 illustrates the arrangement of 2 separators in series, where the effluent of the first separator is

supplied to the second separator. The second separator is equipped with screens of a smaller gap width

than the first separator in order to achieve a further clarifying of the liquid.

Fig. 10-1 Typical arrangement for the operation of 2 separators in series

Inflow