6

3) If a higher pump differential is needed, grip the cord

near the neck of the fl oat, then using the other hand,

exert a steady force on the lower edge of the cable

clamp. The cable clamp should slide up to the new

pivot point. Attach the level control to the discharge

hose in the manner described above.

4) Plug the level control plug into the receptacle, then

plug the pump into the piggyback plug. One cycle of

operation should be observed , so that any potential

problems can be corrected.

5) It is recommended that the fl oat should be set to insure

that the sump well liquid level never drops below the

top of the motor housing or a minimum level of 6

inches above the pump bottom.

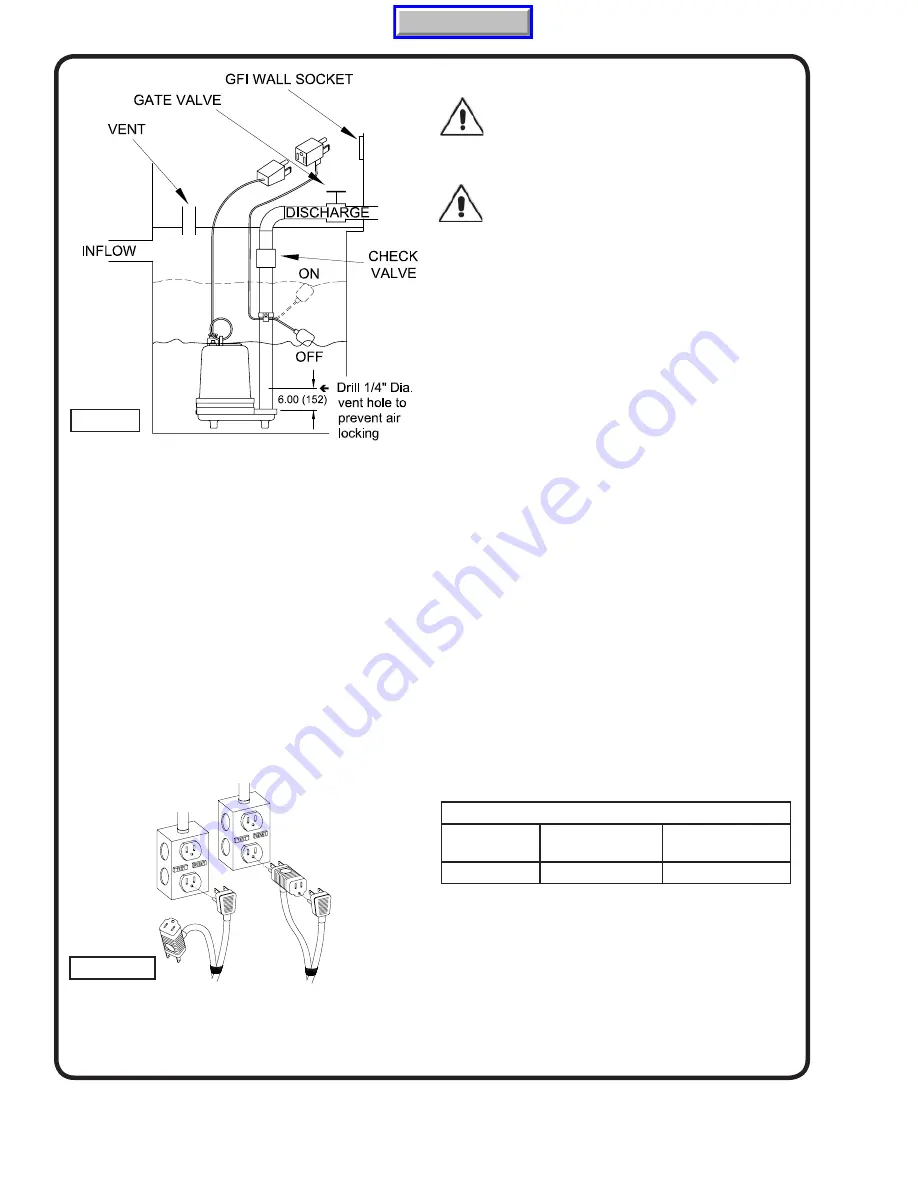

6.) Figure 3 shows a typical connection for pumps with the

wide angle fl oat and piggy-back plug, for manual and

automatic

operations.

Automatic-

Plug fl oat cord into outlet, then plug pump

cord into fl oat cord.

Manual-

Plug pump cord directly into outlet.

C-4) Electrical Connections:

WARNING ! - Pump must be used in a circuit

protected by a ground fault interrupter.

WARNING ! - All model pumps and control

panels must be properly grounded per THE

NATIONAL ELECTRIC CODE or CANADIAN

ELECTRIC CODE and STATE, PROVINCE and

LOCAL electric codes. Improper grounding

voids warranty.

C-4.1) Power Cable:

The cord assembly mounted to the pump must not be

modifi ed in any way except for shortening to a specifi c

application. Any splice between the pump and the control

panel must be made in accordance with the electric codes.

It is recommended that a junction box, if used, be mounted

outside the sump or be of at least NEMA 4 (EEMAC-4)

construction if located within the wet well. Do not use the

power cable to lift pump.

NOTE: THE WHITE WIRE IS

NOT A NEUTRAL OR GROUND LEAD, BUT A POWER

CARRYING CONDUCTOR.

C-4.2) Overload Protection:

Single Phase - The type of in-winding overload protector

used is referred to as an inherent overheating protector

and operates on the combined effect of temperature and

current.

This means that the overload protector will trip out and

shut the pump off if the windings become too hot, or the

load current passing through them becomes too high. It

will then automatically reset and start the pump up after

the motor cools to a safe temperature. In the event of an

overload, the source of this condition should be deter-

mined and rectifi ed immediately.

DO NOT LET THE PUMP CYCLE OR RUN IF AN OVER-

LOAD CONDITION OCCURS !

If current through the temperature sensor exceeds the

values listed, an intermediate control circuit relay must

be used to reduce the current or the sensor will not work

properly.

TEMPERATURE SENSOR ELECTRICAL RATINGS

Volts

Continuous

Amperes

Inrush

Amperes

110-120

3.00

30.0

C-4.3) Wire Size:

Consult a qualifi ed electrician for proper wire size. See

table for electrical information.

FIGURE 3

Manual

Automatic

FIGURE 2

Manual Index

Содержание SE411HT Series

Страница 12: ...12 FIGURE 10 Manual Index...

Страница 13: ...13 FIGURE 11 Manual Index...