18

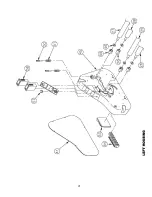

43 10103 TABLE,

FEED

1

44 11539 SUPPORT,

RIGHT

SIDE

1

45 11538 SUPPORT,

LEFT

SIDE

1

46

503

SPACER WASHER

8

47

1319

LIGHT,INDICATOR,RED 120V

1

48

11095

SWITCH, RED (HEAT)

1

49

11094

SWITCH, GREEN (MOTOR & FANS)

2

50

10327

SCREW, ROLLER PRESSURE

4

51

10337

SPRING, ROLLER PRESSURE

4

52

10096

SPRING, MANDREL BRAKE ADJUSTMENT

2

53

574

VARIABLE SPEED CONTROL

1

54

541

TERMINAL BLOCK, 6 STATION

1

55

10113

BUSHING, ROLLER, TOP

4

56

10126

BUSHING, ROLLER BOTTOM

4

57

557

KNOB, MOTOR SPEED

1

58 11596 CONTROLLER,

HEAT

2

59

11535

FEED TABLE GUIDE ASSEMBLY

1

1395

CORD, POWER 14-3

1

11544

DVD, ROLL LAMINATOR

1

1170

FEET, RUBBER, LARGE

4

1172

FUSE HOLDER, MOTOR FUSE

1

11540 FUSE

HOLDER,

POWER

1

11327

FUSE, MAIN POWER 15AMP ABC-15

1

11532

FUSE, MOTOR, 3/4 AMP AGC3/4

1

10386

HEX KEY, ROLLER PRESSURE ADJUSTMENT

1

10389 LABEL,

RIGHT

MIGHTYLAM

1

10387 LABEL,

LEFT

MIGHTYLAM

1

8279 SENSOR,

K

TYPE

1

2856

SHAFT COLLAR, FR12, 1/2"

2

11611 SLITTER

BLADE

ASSEMBLY

2

10232 SWITCH,MOTOR

FORWARD

REVERSE

1

Содержание MIGHTYLAM 2700

Страница 1: ...OPERATING INSTRUCTIONS MIGHTYLAM 2700 ROLL LAMINATOR...

Страница 19: ...19...

Страница 20: ...20...

Страница 21: ...21...

Страница 22: ...22...