5

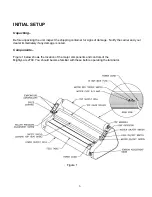

INTRODUCTION

Congratulations on your purchase of the MightyLam 2700 Roll Laminator. This unit is designed to provide

years of trouble-free service.

The MightyLam 2700 will accept rolls of laminating film up to 27” wide in all film thicknesses.

Paper and card stock up to 1/16” (1.6mm) thick may be laminated without adjusting the rollers.

Your

MightyLam 2700 is preset at the factory for most applications so any adjustments should be minor.

Laminator Standard Features...

Preset laminating roller pressure require no adjustment.

Feed table with adjustable guide

Dual digital heat controllers.

Teflon® coated Heat Shoes for easy cleaning.

Laminating film widths up to 27” (68.6cm).

Total material thickness up to 3/16” (4.8mm) with roller adjustment.

SPECIFICATIONS

Plastic Width

Up to 27” (68.6cm)

Plastic Thickness

1.5 mil up to 10 mil (37 to 250 micron)

Maximum Roll Length

1.5 mil - 1,000 feet (304.8 meters)

3 mil - 500 feet (152.4 meters)

5 mil - 250 feet (76.2 meters)

10 mil - 100 feet (30.5 meters)

Speed

0-10 feet per minute (3m/minute)

Net weight

97.5 lbs (44 kg)

Power Requirements

120VAC, 60Hz, 1800 watts

Содержание MightLam 2700

Страница 1: ...OPERATING INSTRUCTIONS MIGHTYLAM 2700 ROLL LAMINATOR ...

Страница 19: ...19 ...

Страница 20: ...20 ...

Страница 21: ...21 ...

Страница 22: ...22 ...