8.7.1 E-Stop Switch Requirements (Positive-Opening)

The E-stop switch must provide two contact pairs, which are closed when the switch is in the armed position. Once

activated, the E-stop switch must open its contacts and return to the closed-contact position only after deliberate action

(such as twisting, pulling, or unlocking).

The switch should be a positive-opening type, as described by IEC947-5-1. A mechanical force applied to such a button (or

switch) is transmitted directly to the contacts, forcing them open. This ensures that the switch contacts open when the

switch is activated.

ANSI/NFPA 79 specifies the following additional requirements:

• Emergency Stop push buttons shall be located at each operator control station and at other operating stations

where emergency shutdown shall be required.

• Stop and Emergency Stop push buttons shall be continuously operable from all control and operating stations

where located.

• Actuators of Emergency Stop devices shall be colored red. The background immediately around the device actuator

shall be colored yellow. The actuator of a push-button-operated device shall be of the palm or mushroom-head

type.

• The Emergency Stop actuator shall be a self-latching type.

Some applications may have additional requirements. The user must comply with all relevant regulations.

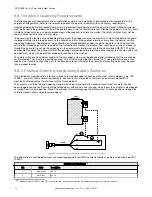

WARNING: Connecting multiple e-stop switches

• When two or more e-stop switches are connected to the same EZ-SCREEN receiver, the

contacts of the e-stop switches must be connected together in series. This series combination is

then wired to the respective EZ-SCREEN receiver input.

• Never connect the contacts of multiple e-stop switches in parallel to the EZ-SCREEN inputs; this

defeats the switch contact monitoring ability of the EZ-SCREEN light curtain, and creates an

unsafe condition which could result in serious bodily injury or death.

• Also, when two or more e-stop switches are used, each switch must be individually actuated

(engaged), then re-armed and the EZ-SCREEN light curtain reset (if using latch mode). This

allows the monitoring circuits to check each switch and its wiring to detect faults. Failure to test

each switch individually in this manner could result in undetected faults and create an unsafe

condition which could result in serious bodily injury or death.

WARNING:

• Reset Routine Required

• Allowing the machine to restart as soon as the e-stop switch is armed creates an unsafe

condition that could result in serious injury or death.

• U.S. and international standards require that a reset routine be performed after returning the e-

stop switch to its closed-contact position (when arming the e-stop switch). When automatic reset

is used, establish an alternate means to require a reset routine after the e-stop switch is armed.

8.8 Interlock Switches in Cascaded Systems

The Cascade input may be used to monitor interlock safety gates or guards. Requirements vary widely for the level of

control reliability or safety category (per ISO 13849-1) in the application of interlocked guards. While Banner Engineering

recommends the highest level of safety in any application, the user is responsible to safely install, operate, and maintain

on page 74 meets or exceeds the requirements for OSHA/ANSI control reliability and Safety

Category 4, per ISO 13849-1.

WARNING:

• The hazard must be accessible only through the sensing field

• Incorrect system installation could result in serious injury or death.

• The installation of the EZ-SCREEN must prevent any individual from reaching around, under, over

or through the defined area and into the hazard without being detected.

• See OSHA CFR 1910.217, ANSI B11.19, and/or ISO 14119, ISO 14120 and ISO 13857 for

information on determining safety distances and safe opening sizes for your guarding device.

Mechanical barriers (for example, hard (fixed) guarding) or supplemental safeguarding might be

required to comply with these requirements.

EZ-SCREEN

®

14/30 mm Safety Light Screen

www.bannerengineering.com - Tel: + 1 888 373 6767

73