Door Lock Operation

Operation

The lock system uses a "push-to-open /

push-to-close" style mechanism which

differentiates it from any other door lock in

the industry. This design was developed as

a result of analyzing the shortcomings of

other door lock mechanisms on the market.

It hence has many fundamental safety &

mechanical advantages.

Operation

Opening & Closing

To open the door the machine must not be

running a wash program -- "Program N"

should be displayed on the EL6. Simply

push and release the door handle with the

palm of your hand. As you push the handle

in the door lock solenoid will energize and

the pin will retract and release the door.

Then as you release the pressure on the

handle the door will be free and you can

pull it open. To close the door swing it

closed, then push the handle firmly until

you hear the solenoid engage, releasing the

door lock pin to lock the door. When you

start a wash program the door lock is

securely disabled so that the door cannot be

accidentally opened.

·

Periodic Maintenance

>

The door should be tested every day for

safe operation by trying to start a program

with the door open. If the machine will

begin operation in this state it should

immediately be removed from service,

locked out, and a qualified service

technician called to repair it.

>

If the door lock is malfunctioning in any

way, the machine should immediately be

removed from service, locked out, and a

qualified service technician called to repair

it.

>

The door lock pin and handle hinge

should be lubricated with "silicon spray

lube" monthly. This product is available at

almost any auto parts store. This procedure

does not require any disassembly.

>

The door handle nose bushing should be

checked for wear and cracking monthly. It

should be replace when it is cracked,

missing, or worn out.

>

The door lock tongue and lock pin

alignment should be checked monthly and

adjusted as needed.

>

For detailed instructions on door

alignment, request TSB009 when

contacting technical service.

30

Содержание HP series

Страница 2: ......

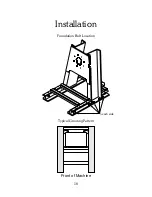

Страница 19: ...Front of Machine 18 Installation Foundation Bolt Location Typical Grouting Pattern 5 each side...

Страница 38: ......