BTL5-A/C/E/G_ _-M/U_ _ _ _-P-S 32/KA_ _

Micropulse Linear Transducer in Profile Housing

6

english

4

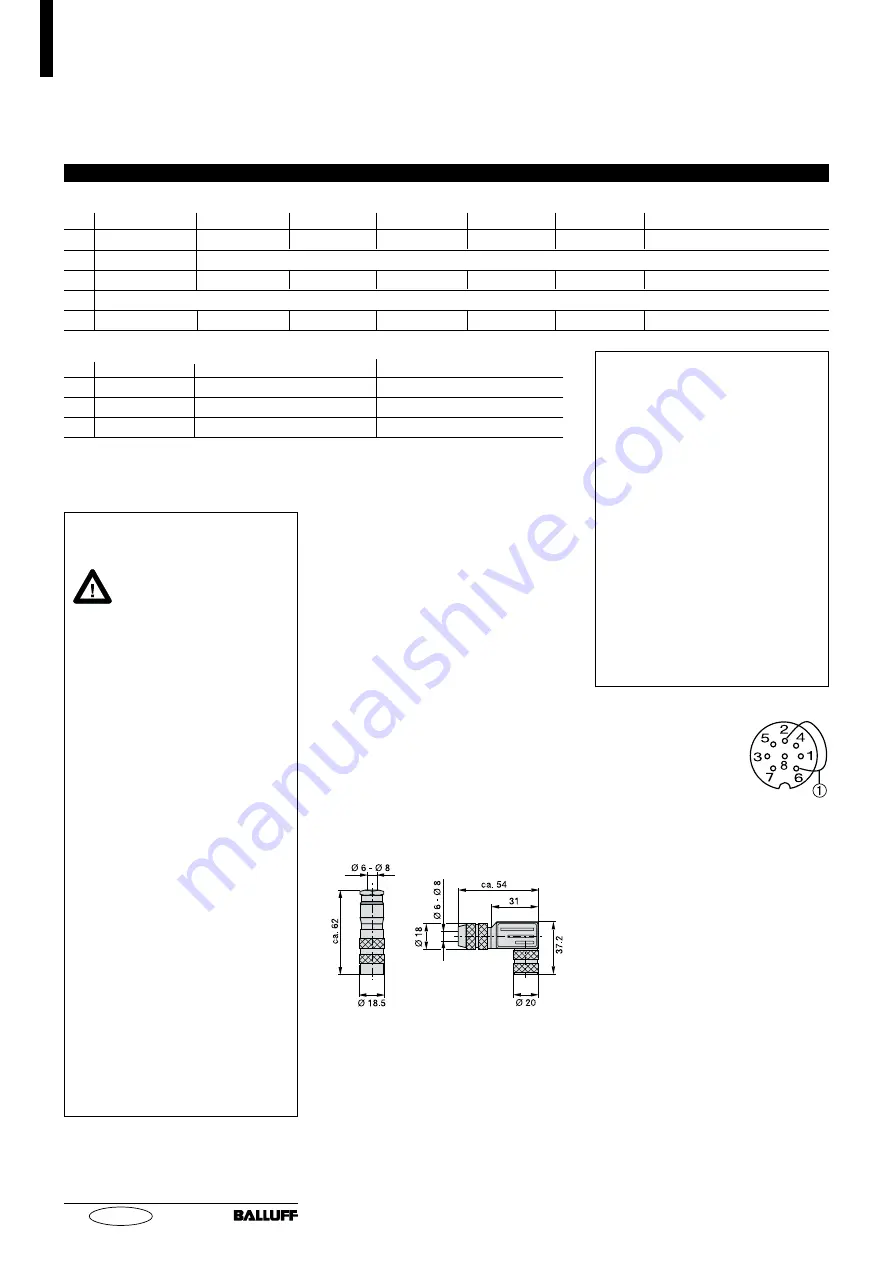

Wiring

Note the following when making

electrical connections:

System and control cabi-

net must be at the same

ground potential.

To ensure electromagnetic com-

patibility (EMC), which Balluff

verifies by the CE Marking, the

following points must be strictly

observed.

BTL transducer and the proces-

sor/control must be connected

using shielded cable.

Shielding: Copper filament

braided, 80% coverage.

The shield must be tied to the

connector housing in the BKS

connector (

➥

➥

➥

➥

➥

Fig. 4-1); see in-

structions accompanying the con-

nector.

In the cable version the cable shield

is connected to the housing in the

PG fitting.

The cable shield must be

grounded on the control side, i.e.,

connected to the protection

ground.

Pin assignments can be found in

➥

➥

➥

➥

➥

Table 4-1. Connections on the

controller side may vary according

to the controller and configuration

used.

When routing the cable between the

transducer, controller and power

supply, avoid proximity to high volt-

age lines to prevent noise coupling.

Especially critical is inductive noise

caused by AC harmonics (e.g. from

phase-control devices), against

which the cable shield provides only

limited protection.

Cable length max. 20 m; Ø 6 to

8 mm. Longer lengths may be used

if construction, shielding and routing

are such that external noise fields

will have no effect on signal integrity.

Fig. 4-2: Pin assignments BKS,

connector type BTL

BKS connector,

view towards solder

side of female

BKS-S 32M-00 or

BKS-S 33M-00

Table 4-1: Wiring assignment

straignt

BKS-S 32M-00

No. 99-5672-19-08

(Binder part no.)

right-angle

BKS-S 33M-00

No. 99-5672-78-08

Fig. 4-1: Connector (optional)

Cable entry

(PG 9 fitting)

Output signals

Pin

Cable

BTL5-A_1

-C_0

-C_7

-E_0

-E_7

-G_1

1

YE

yellow

not used

➂

0...20 mA

20...0 mA

4...20 mA

20...4 mA

not used

➂

2

GY

grey

0 V

➀

3

PK

pink

➁

10...0 V

10...0 V

10...0 V

10...0 V

10...0 V

10...–10 V

4

not used

5

GN

green

➁

0...10 V

0...10 V

0...10 V

0...10 V

0...10 V

–10...10 V

Supply voltage (external)

Pin

Cable

BTL5-A/C/E/G1_

BTL5-A/C/E/G2_

6

BU

blue

GND

➀ ➃

GND

➀ ➃

7

BN

brown

+24 V

+15 V

8

WH

white

do not connect

–15 V

➀

The analog transducer outputs

are potential-free. When connect-

ing to a module with non-poten-

tial-free inputs, ground loops may

cause erroneous signals. Avoid

this by defeating the potential-

free function in the transducer:

jumper Pin 2 and Pin 6 in the

female connector (

➥

➥

➥

➥

➥

Fig. 4-2).

➁

A small voltage difference

(< 10 mV) appears between pin 3

and 5 due to seperate output

drivers.

➂

Unused leads can be tied to

GND on the control side, but they

must never be connected to the

shield.

➃

Reference GND for supply

voltage and EMC!