Section 5

Troubleshooting and Maintenance

Troubleshooting and Maintenance 5-1

MN2412

Maintenance

This manual contains only very minimal engine maintenance instructions. Refer to the engine

manufacturer’s owner’s manual for specific engine maintenance instructions for your generator

set. Any maintenance instructions or recommendations in the engine owner’s manual take

precedence over any of the following general recommendations.

General:

1.

Inspect the fuel system for leaks. Replace all defective components immediately.

2.

Inspect and replace any fuel line that shows signs of deterioration.

3.

Inspect all fuel clamps to ensure they are tight.

4.

Make sure the fuel cap fits snugly on the fuel tank and that the fuel tank does not leak.

5.

Inspect and clean the battery posts and the associated battery cable terminals.

6.

Inspect the external wire cables and connectors used with the generator set for cuts,

frayed insulation, or loose connections. Repair or replace damaged parts before use.

7.

The engine should be checked for proper speed setting(s).

Prior to adjusting the engine speed, turn the auto idler switch to “OFF” (if present).

Make sure that the auto idler magnet does not touch the throttle lever of the engine

when running.

a.

Disconnect all electrical loads and start the engine.

b.

Adjust the engine speed to 3720 RPM (62 Hz) with no load speed.

c.

Adjust the auto idler speed after you have accomplished the above adjustment.

d.

Adjust the auto idler speed by moving the electro

−

magnet back and forth in the

magnet bracket to achieve an engine RPM of 2500

−

2900 with the auto idler switch

“ON”.

8.

Test all GFCI receptacles monthly by pressing the test button on the receptacle and

making sure that the GFCI trips and and no voltage is present at the receptacle.

Replace any GFCI receptacle that fails the test.

Engine:

1.

Clean and/or replace any fuel, oil, and/or air filters per the engine manufacturers’

guidelines.

2.

Check oil level regularly; at least every 5 to 8 operating hours. Maintain the proper oil

level.

3.

Change the oil as is recommended in the engine manufacturer’s owner’s manual.

4.

Replace the spark plug(s) as is recommended by the engine manufacturer.

5.

Clean the cooling fins on the engine to keep the engine’s heat dissipation potential at

it’s maximum.

6.

Inspect and clean all governor and carburetor linkages so they operate properly.

7.

Inspect the recoil starting rope for any damage and replace it if necessary (if

applicable).

8.

Clean the trash screen around the recoil starter or other cooling air intake.

Alternator:

( also called Generator End)

This generator set must be run at its proper speed to obtain the correct electrical power at its

output. All engines have a tendency to slow down when a load is applied to it. The engine

governor is designed to hold the operating speed as nearly constant as possible. When the

electrical load is increased, the engine is more heavily loaded and engine speed drops slightly.

This slight decrease in engine speed results in a slight decrease in generator voltage and

frequency output. This voltage and frequency variation has no appreciable effect in the operation

of motors, lights, and most appliances and tools. However, timing devices and clocks will not

keep perfect time when used on this generator.

1.

Clean the generator set and remove any and all dust, dirt, or other foreign material.

2.

Inspect and clean the cooling air intake and exhaust louvers of the generator end.

Make sure they are clean. Remove dirt or any buildup that may restrict the cooling air

flow.

3.

Clean the generator set and its components with a damp cloth or sponge.

Never use a water hose or pressure washer as this may damage electrical

components.

4.

Inspect and replace any control panel components that are broken or not working

properly (receptacles, circuit breakers, switches, etc.)

Содержание PC Series

Страница 1: ...PowerchiefR POW R Products Generator Series PC Installation Operating Manual 5 05 MN2412...

Страница 4: ...ii Table of Contents MN2412...

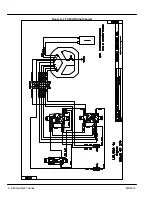

Страница 26: ...A 4 PowerchiefR Series MN2412 Figure A 5 PC30H Wiring Diagram...

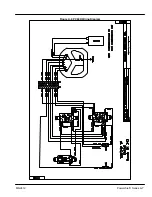

Страница 27: ...PowerchiefR Series A 5 MN2412 Figure A 6 PC40H Wiring Diagram...

Страница 28: ...A 6 PowerchiefR Series MN2412 Figure A 7 PC50H Wiring Diagram...

Страница 29: ...PowerchiefR Series A 7 MN2412 Figure A 8 PC60H Wiring Diagram...

Страница 30: ...A 8 PowerchiefR Series MN2412 Figure A 9 PC90VE Wiring Diagram...