Service Bulletin SB 1074

Rev. H 12/15

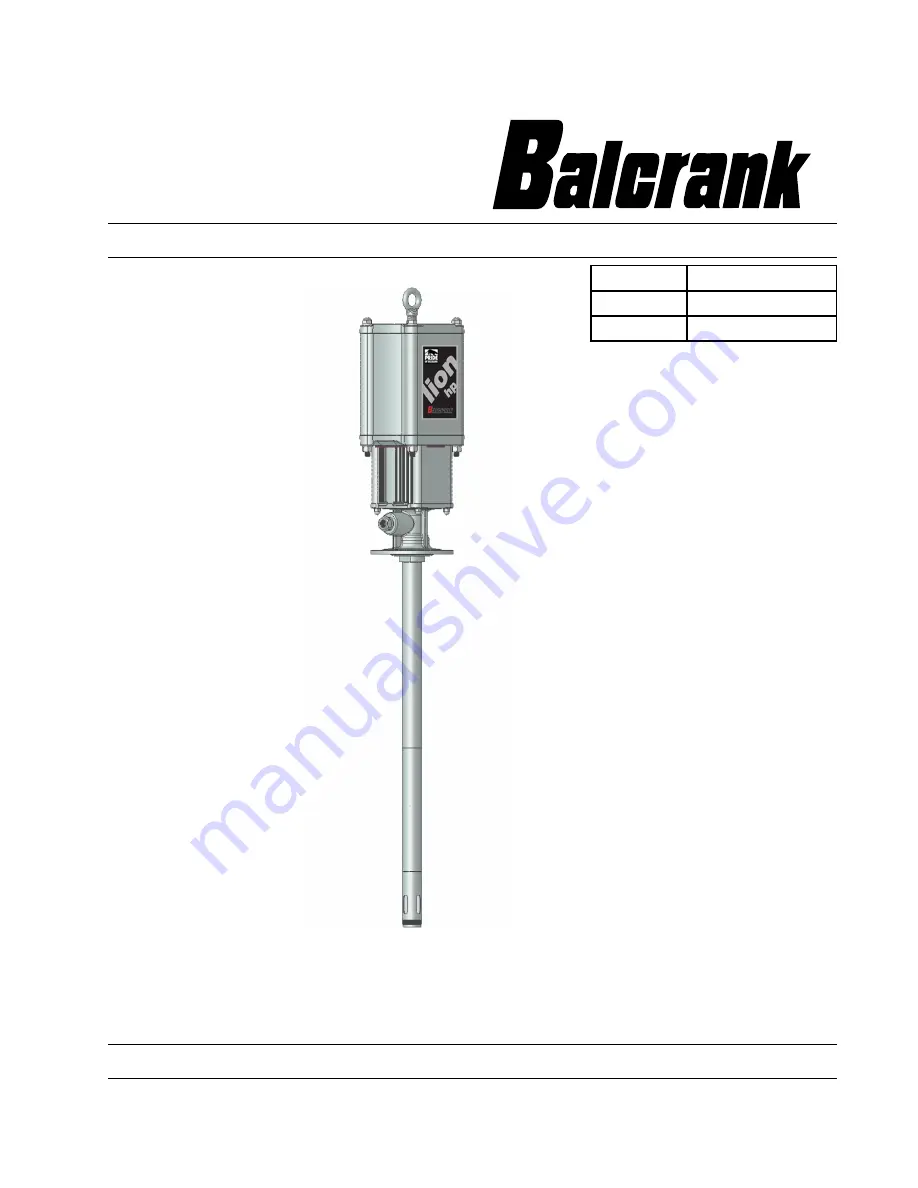

Lion HP

®

50:1 Grease Pump Series

Operation, Installation, Maintenance and Repair Guide

Thoroughly read and understand this manual before

installing, operating or servicing described equipment.

®

Model #

Pump Version

1150-015 400lb. Drum

1150-018 Tote Stub