-36-

5.

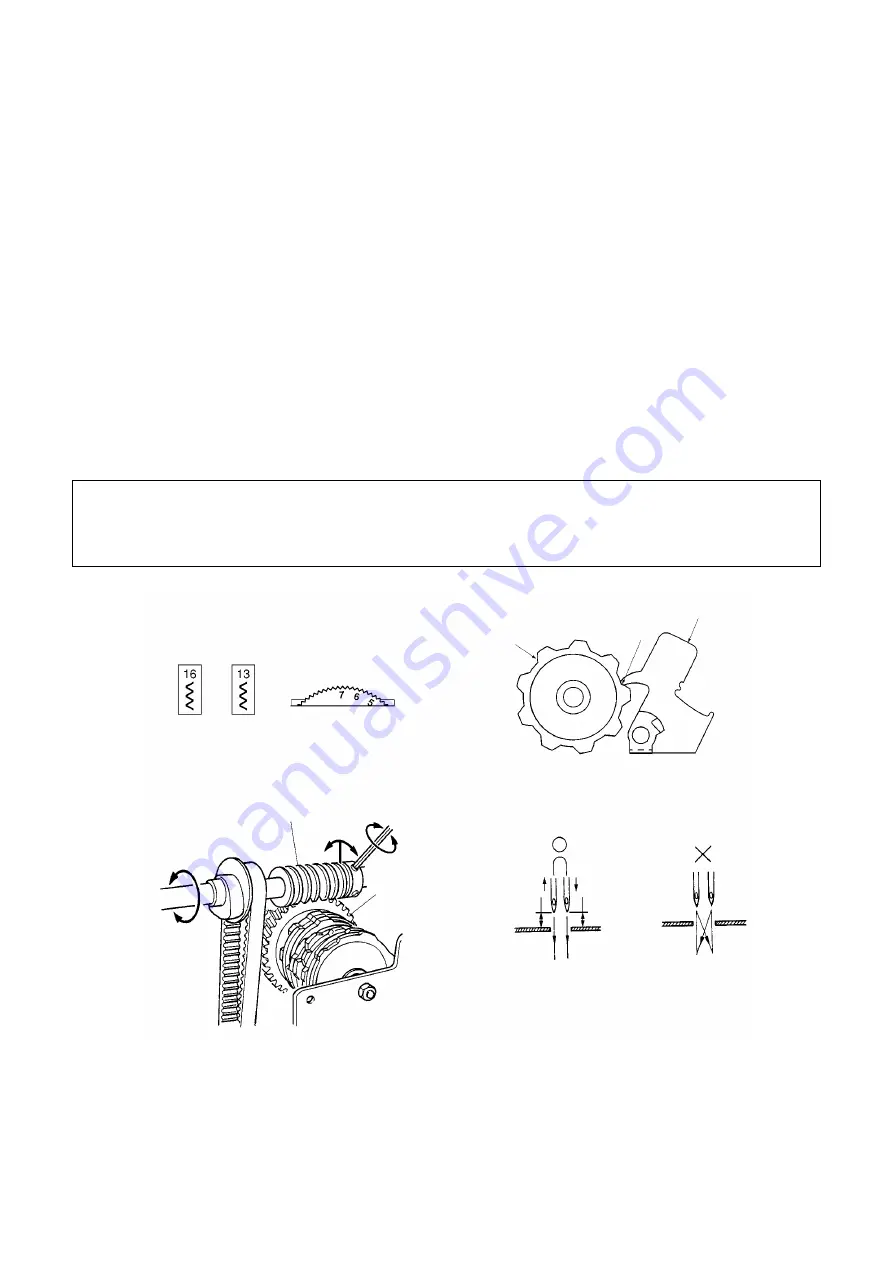

NEEDLE FLOW

STANDARD

For zigzag sewing, the distance from the needle plate upper surface to the tip of the needle (#14) when the

needle bar starts oscillating movement should be 5.6

±

0.4 mm. Also, the distance from the needle plate top

surface to the needle (#14) tip when the needle bar oscillating movement stops must be 7.8

±

0.4 mm.

ADJUSTMENT

1.

Turn the selection dial to select zigzag sewing.

2.

Turn the Zigzag dial to the maximum.

3.

Loosen the three screws securing the worm gear.

4.

Turn the balance wheel, raise the needle bar from bottom dead center, and fasten the needle bar at a

position where the distance from the needle plate top surface to the needle tip (#14) is 5.6 mm.

5.

Turn the worm gear or pattern cam to put the Z finger and pattern cam in the state shown in Figure A.

6.

Tighten the three screws securing the worm gear.

7.

Turn the balance wheel and check how the needle flows.

Adjustment Points

6.

At this time, adjust the meshing of the worm gear and pattern cam gear. Adjust the meshing so that the

play on the pattern cam is no more than 0.1 mm at the outer edge of the cam and so that the balance

wheel turns freely by hand.

Pattern

cam gear

Worm gear

Figure A

Z finger

Contact

Pattern cam

7.8

±

0.4 mm

(Oscillation stop)

5.6

±

0.4 mm

(Oscillation start)

∗

When the needle flows from left to right

(BL6300)

(BL6800)

Содержание BL-6800

Страница 1: ...6 2001...

Страница 4: ...2 1 MECHANICAL CHART...

Страница 8: ...6 3 ELECTRONIC PARTS ARRANGEMENT CHART BL6800 only...

Страница 31: ...29 2 LEAD WIRES ARRANGEMENT BL6800 BL6300...

Страница 72: ...70 SS VR board BL6800 only 1 pin Start Stop switch Speed volume...

Страница 76: ...BL 6800 BL 6300 H1060208...