Before performing any maintenance or cleaning work, always turn off the engine and wait

until the generator has come to a standstill.

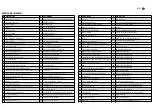

CONDITION

PROBABLE CAUSE

CORRECTIVE

ACTION

Loose spark plug

Tighten plug

properly

Insufficient

compression

Loose cylinder

head bolt

Tighten bolt

properly

Damaged gasket

Replace gasket

Fuel

systems

problems

Insufficient

pulling speed

for starting rope

Pull rope

sharply

Engine

won’t start

No fuel

supplied to

combustion

chamber

Foreign matter

in fuel tank

Clean tank

Clogged

fuel line

Clean fuel line

Low engine

output

No fuel in tank

Supply fuel

Fuel shutoff

not open

Open valve

Engine run

erratically

Electric

systems

problems

Spark plug dirty

with carbon

or wet with fuel

Remove carbon

or wipe up

spark plug

Sufficient

compression

Improper

spark

Damaged

spark plug

Replace

spark plug

Combustion

chamber

supplied

with fuel

Faulty

magneto

Improper

adjustment of

carburetor

Consult dealer

Improper

spark

Insufficient

pulling speed

for starting rope

Pull rope

sharply

Improper

grade

of fuel used

Check fuel

Overloading

Check

the working

condition

Overheating

D

GB

Changing the engine oil

CAUTION: prolonged exposure to used engine oil is dangerous; always wash your hands

thoroughly after handling used engine oil.

1. Unscrew and remove the oil filler cap/dipstick.

2. Place a oil collection tray under the drain plug.

3. Unscrew the drain plug, and allow the used engine oil to drain from the crankcase into

the oil collection tray.

NOTE: Drain the engine oil when the engine is warm, this will ensure the oil flows out

quicker.

4. Replace the drain plug and its seal ring.

5. Fill the crankcase with engine oil to the ‘H’ mark on the dipstick.

6. Replace the oil filler cap/dipstick.

NOISE/VIBRATION INFORMATION

Measured sound values determined according to EN ISO 3744:1995.

Wear hearing protection!

Vibration total values (triax vector sum) determined according to EN ISO 3744:1995: The

vibration emission level given in this information sheet has been measured in accordance

with a standardized test given in EN ISO 3744:1995 and may be used to compare one tool

with another. It may be used for a preliminary assessment of exposure. The declared

vibration emission level represents the main applications of the tool. However, if the tool

is used for different applications, with different accessories or poorly maintained, the

vibration emission may differ. This may significantly increase the exposure level over the

total working period. An estimation of the level of exposure to vibration should also take

into account the times when the tool is switched off or when it is running but not actually

doing the job. This may significantly reduce the exposure level over the total working

period. Identify additional safety measures to protect the operator from the effects of

vibration, such as maintaining the tool and the accessories, keeping hands warm,

adjusting work patterns to avoid risk of vibration.

DISPOSAL AND RECYCLING

The unit is supplied in packaging to prevent its being damaged in transit. This packaging

is raw material and can therefore be reused or can be returned to the raw material system.

The unit and its accessories are made of various types of material, such as metal and

plastic. Defective components must be disposed of as special waste. Ask your dealer or

your local council.

One of the most damaging sources of pollution is oil; Do not throw away used engine oil in

with your domestic trash or down drains and sinks. Place it in a leak proof container and

take it to your local waste disposal site.

GB

IT

108

107

|

GB

TROUBLE SHOOTING