Trouble Shooting

16

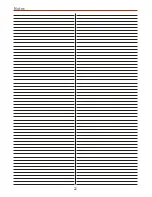

PROBLEM

CAUSE

REMEDIAL ACTION

Tank pressure drops.

Leakage at connections

or joints.

Set the compressor to maximum

pressure. Switch off and brush

a soapy water solution onto all

connections and joints. Look for

bubbles. Tighten connections or

joints where leakage is visible.

The pressure switch valve

leaks when the compressor

is stopped.

Non-return valve seal

dirty or defective.

Release any air in tank by pulling

the ‘PRV’ valve and contact our

technical team at Axminster

Tools & Machinery.

The compressor stops

and will not start again.

Bad electrical connections.

Check the connections. Clean

and tighten as necessary.

Current over-load protector

or over-heat protector has

activated.

Press the reset button (FA-3050V)

on the current over-load and wait

for a minute. The motor will run

when it has cooled.

Motor winding burnt out.

Contact our techical team at

Axminster Tools & Machinery for

assistance.

Compressor head gasket blown

or valve broken.

Contact our technical team at

Axminster Tools & Machinery for

assistance. 0800 371822

The compressor does not reach

the set pressure and overheats.

Crank bearing failure.

Stop the compressor and contact

our technical team at Axminster

Tools & Machinery for assistance.

The compressor is noisy.

Repetitive metallic clanking.

Pressure switch failure.

Stop the compressor quickly.

Release any air in tank by pulling

the ‘PRV’ valve and contact our

technical team at Axminster

Tools & Machinery.

Содержание Craft AC21C

Страница 5: ...Assembly 5 Fitting the RearWheels 1 2 3 4 5 6 7 8 Continues Over ...

Страница 6: ...Assembly 6 Fitting the Rubber Feet Fitting the Air Filters 1 3 2 4 2 1 Remove transport plug 3 ...

Страница 17: ...Wiring Diagram 17 ...

Страница 18: ...Exploded Diagram Parts List AC21C 18 ...

Страница 20: ...Exploded Diagram Parts List AC44C 20 ...

Страница 22: ...Notes 22 ...

Страница 23: ...Notes 23 ...