5

Assembly

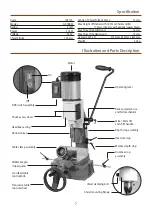

Please take some time to read the section entitled

“Illustration and Parts Description” to identify the

various parts of your machine so that you are familiar

with the terminology we will use to enable you to set

up and operate your Morticer safely and correctly.

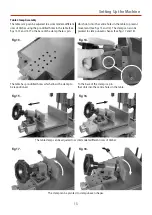

Place the machine onto a suitable surface, at a height that

will enable you to work comfortably and to ensure that

there is adequate room on either side for the size of timber

you plan to use. Once you are happy bolt the morticer

down. Loosen the locking caphead screw (a) to raise the

morticers head assembly. Locate the operating lever (A)

and the M6 x 16mm lift and shift handle (E), introduce the

operating lever through the rack and pinion assembly,

then secure the lever in place using the M6 lift and shift

handle (E) (See fig 2).

Locate the operating wheel Shaft (C), remove the phillips

screw, clamping washer and M6 x 23mm caphead screw

and place them safely aside (See figs 3 and 5). Slide

the machined cutout onto the transverse table shaft

mechanism, line up the pre-drilled hole with the one in the

table shaft mechanism and secure them in position using

a 5mm allen key and the M6 x 23mm caphead screw you

removed earlier (See figs 4 and 5).

Rack and pinion assembly

Remove the phillips screw

and clamping washer.

Secure the wheel shaft (C) to the table

shaft using the M6 caphead screw.

Slide the operating wheel (B)

onto the operating shaft (C).

Locating

key

Slot

Slide the machined cutout onto the

transverse table shaft mechanism.

Table shaft

mechanism

Fig 1.

Fig 3.

Fig 2.

Fig 4.

Fig 6.

A

C

C

B

E

a

Fig 5.

M6 Caphead

screw

Содержание AC16BM

Страница 1: ...AC16BM Bench Morticer AT M 21 03 2019 BOOK REF 105799 Code 105114 Original Instructions ...

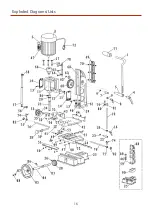

Страница 16: ...16 Exploded Diagrams Lists ...

Страница 18: ...18 Notes ...

Страница 19: ...19 Notes ...