2. INSTALLATION

A. Connect the inlet flange with the water main. To prevent pipe joint separation restrain the movement of the

hydrant with appropriate thrust blocking or with restraining joints. Make sure the soil is compact around the

barrel to support the lower barrel against side loading. If the soil is too sandy and does not support the loads,

the barrel can be supported by pouring a concrete pad of at least 6 inches in thickness and 24 inches in

diameter around the barrel at or near the bury line.

To provide drainage, place clean coarse gravel or crushed stone from the bottom of the trench to at least 6

inches above the drain opening in the hydrant and to a distance of 1 foot around the elbow. For clay or other

impervious soils, excavate a drainage sump 2 feet in diameter and 3 feet deep below each hydrant. Fill the

sump with clean coarse gravel or crushed stone to a level of 6 inches above the drain opening.

Place a plastic sheet over the gravel to prevent dirt from clogging the drains.

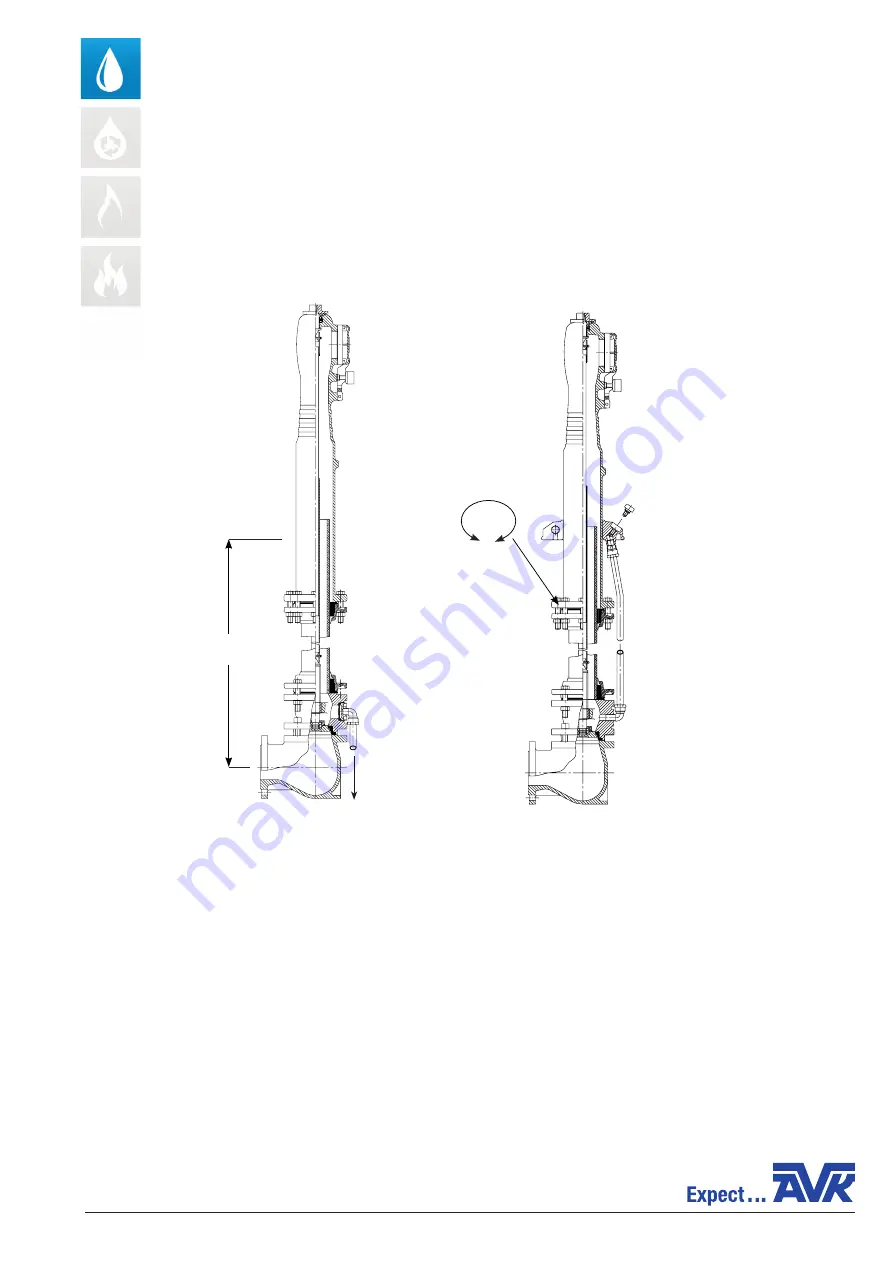

B. The ground cover can be placed above ground level since the hydrant is height adjustable and the outlet can

be placed in any requested position because of the 360° rotatable upper barrel.

When you assemble the upper part of the hydrant of the last 200 mm of the riser pipe from the lower part, a

support bush must be fitted – request this separately (see datasheet 05-E-008 for specification of bush).

COPYRIGHT©AVK GROUP A/S 2020 - AVK INTERNATIONAL A/S, Bizonvej 1, DK-8464 Galten - www.avkvalves.eu

9632500054 _rev AD_UK

INSTALLATION & MAINTENANCE INSTRUCTIONS - ORIGINAL VERSION

AVK ABOVE GROUND FIRE HYDRANT, TYPE A & B, DN80/DN100

SERIES 09

Max. operation pressure: 10 bar

Max. operating temperature: 20°C

1. TECHNICAL DATA

Manual drainage

Automatic drainage

for fascine

Height adjustable

1050-1550mm

360°

rotatable