2. Fonts, Bar Codes and Graphics Specification

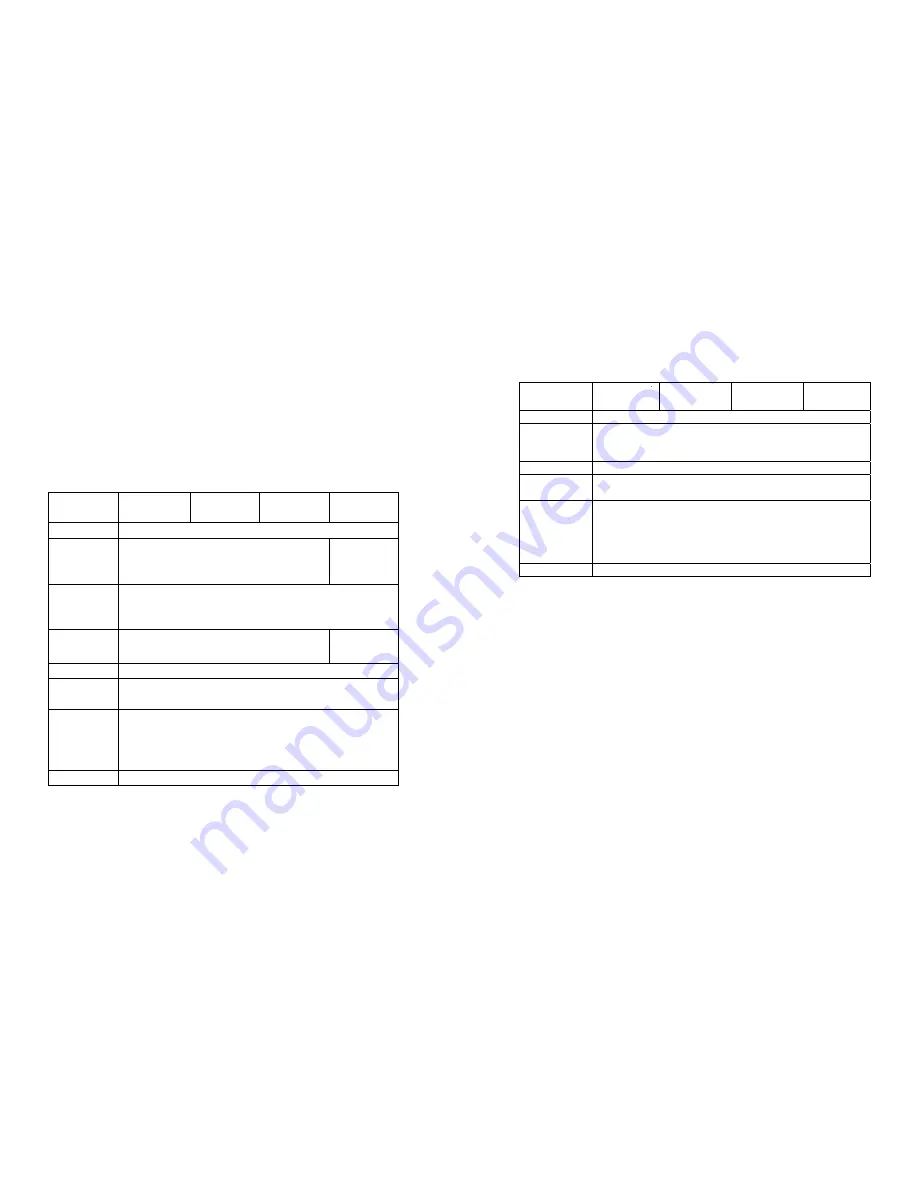

Printer Programming Language B, PPLB

Specification

Model

OS-202DT

Model

OS-204DT

Model

AP 2.4

Model

OS-314TT

General fonts 5 fonts with different point sizes

Symbol sets

(Code pages)

8 bits: code page 437, 850, 852, 860, 863 and 865. 7

bits: USA, British, German, French, Danish, Italian,

Spanish, Swedish and Swiss.

Soft fonts

Downloadable soft fonts

Font

expandability

1x1 to 24x24

Bar code

types

Code 39(checksum), Code 93, Code 128/ subset A,B,C,

Codabar, Interleave 2 of 5(checksum), Matrix 25, UPC

A/E 2 and 5 add-on, EAN-8/13, Code 128UCC,

UCC/EAN, Postnet, German Postcode. MaxiCode and

PDF417 (2D symbologies)

Graphics

PCX and binary raster

The specifications of fonts, bar codes and graphics depend on the

printer

interpreter

. The emulation is a printer programming

language, through which the host can communicate with your

printer. There are two printer programming languages for models

202/204/214/314, they are PPLAand PPLB.

Printer Programming Language A, PPLA

Specification

Model

OS-202DT

Model

OS-204DT

Model

AP 2.4

Model

OS-314TT

General fonts

7 alpha-numeric fonts, OCR A and OCR B ASD

Smooth fonts

6, 8, 10, 12, 14 and18 points

4, 6, 8, 10,

12, 14 and 18

points

Symbol sets

for fonts

smooth

USASCII, UK, German, French, Italian, Spanish,

Swedish, and Danish/Norwegian

Courier fonts

8 symbol set (PC, PC-A,PC-B EAMA-94,

Roman8, Legal,

Greek and Russian)

X

Soft fonts

Downloadable PCL fonts

Font

expandability

1x1 to 24x24

Bar code

types

Code 39, Code 93, Code 128/subset A,B,C, Codabar,

Interleave 2 of 5, UPC A/E/2 and 5 add-on, EAN-8/13,

UCC/EAN-128, Postnet, Plessey, HBIC, Telepen and

FIM. MaxiCode and PDF417 (2D symbologies).

Graphics

PCX, BMP, IMG and HEX formats

Notes :

1. The bare core for ribbon must be 11 cm in length. It should

have two opposite slits at two ends. If the ribbon itself is

less than 11 cm, it has to be aligned with the bare core at

left end when you install it.

2. Since this printer uses band buffer technology, if you just

print texts or barcodes the maximum length can be more

than 30 inches, whereas if you print many graphics the

maximum length can only be few inches under standard

onboard RAM.(The extension RAM, font board and flash

modules use the same connector, they cannot function at

the same time.)

53

54