Page 2

OPERATION

The Positioner has a usual pressure range of 10 to 60 psi (0.7

to 4.1 bar) within a temperature range of -40°F to 165°F (-40°C

to 74°C). Pressure is supplied by a pressure control valve such

as the AVENTICS CONTROLAIR

®

Valve or FLEXAIR

®

Valve.

The pressure imposed on the diaphragm (6) is proportional to

the handle travel of the control valve. The movement of the

positioner operating lever (14) is also proportional to this

movement. Finally, the position of the controlled device is

proportional to the handle travel of the control valve.

When supply pressure is reduced, the force of the spring (8)

against the push rod and spring seat assembly (7) returns the

lever to its new position corresponding to the value of air

pressure remaining. Supply pressure of 10 psi (0.7 bar) usually

provides idle position with 60 psi (4.1 bar) usually providing full

travel or full fuel position.

MAINTENANCE

By removing only the cover (5), the diaphragm (6) can be

quickly replaced without removing the positioner from its

mounting or disturbing the piping connection.

When complete disassembly is required, clean all metal parts

with a nonflammable solvent and wash all rubber parts with

soap and water. Rinse thoroughly and blow dry with a low-

pressure air jet. Replace those parts which are damaged or

worn, giving particular attention to the condition of the

diaphragm (6).

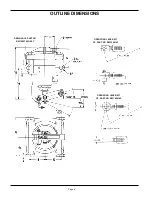

Reassemble the positioner using the exploded and assembly

views as reference. No special tools are required. To maintain

the same preload on the spring (8), shims (9 and 10) must be

included. Apply Number 107 Lubriplate, or its equivalent, to all

grease fittings.

CONVERSION AND REPAIR KITS

Conversion Kits are available for A-2-H Actuator Positioners of previous designs. If the body castings are still in good condition,

these positioners should be converted to the current design at the earliest convenient maintenance period.

KIT Part Number R431005741 (Old Part Number P -061277-00000)

Will convert all A-2-H Actuator Positioners using lever Part Number 521100, prior to those listed in the Identity Schedule below.

IDENTITY SCHEDULE

PRESSURE

RANGE

WITH ACCESSORIES PART

LESS ACCESSORIES

ACCY. KIT

New P/N

Old P/N

New P/N

Old P/N

New P/N

Old P/N

3-15

R431005217 P -059718-00011 R431005216 P -059718-00010 R431004143 P -057415-00000

10-60

R431004010 P -057159-00011 R431004009 P -057159-00010 R431004143 P -057415-00000

10-60

R431004011 P -057159-00012

--

--

R431004145 P -057416-00000

10-60

--

--

*R431005745 *P -061289-00010

--

--

15-80

R431004529 P -058430-00011 R431004528 P -058430-00010 R431004143 P -057415-00000

35-90

R431003984 P -057086-00011 R431003983 P -057086-00010 R431004143 P -057415-00000

REF. QTY

DESCRIPTION

5

1 COVER, Diaphragm

6

1 DIAPHRAGM

7

1 PUSH ROD and SPRING SEAT ASSEMBLY, Complete

REF. QTY

DESCRIPTION

1

1 NUT, #10-32 Stop

2

1 BOLT, 1/4" Pivot

3

1 BEARING, 1/4" ID.

5

1 COVER, Diaphragm

6

1 DIAPHRAGM

7

1 PUSH ROD and SPRING SEAT ASSEMBLY, Complete

11

1 NUT, 1/4"-28 Stop

12

1 BOLT, 5/16" Pivot

13

1 BEARING, 5/16" ID.

14

1 LEVER

KIT PART NUMBER R431005999 (Old Part Number –062065-00000)

Will convert A-2-H Actuator Positioners listed as “Obsolete” in the Identity Schedule below to current design.

* Uses body (ref. 17a, page 3) with drain hole for mounting Positioner with lever in top position.

PART NO.

OLD PART NO.

DESCRIPTION

R431005743 P -061278-00000 Repair kit - minor kit (includes diaphragm & bearings, ref. items 3, 6 & 13)

R431006212 P -063286-00000 Repair kit - major kit (includes minor kit (above) plus ref. items 1, 2, 11, 12 and 14.