13 (28)

.

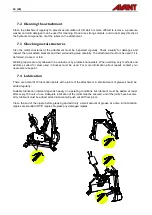

Step 5:

Complete the assembly by tightening four

M16 screws against the quick coupling

plate of the loader. Use an 8 mm Allen

key.

Backhoe

can

be

operated

without

tightening these screws, but more rigid

coupling will improve overall performance.

5.2

Connecting and disconnecting the hydraulic hoses

On the 200 series 2 loaders the hydraulic hoses are connected using the multi connector system.

VAROITUS:

Never connect or disconnect quick couplings or other hydraulic components

while the control lever of the auxiliary hydraulics control lever is locked on or if the system

is pressurized. Connecting or disconnecting the hydraulic couplings while the system is

pressurized may lead to unintended movements of the attachment, or ejection of

high-pressure fluid, which can cause serious injuries or burns. Follow safe stopping

procedure before disconnecting hydraulics.

Keep all fittings as clean as possible; use the protective caps on both the attachment and

the loader. Dirt, ice, etc. may make using the fittings significantly more difficult. Never

leave the hoses hanging on the ground; place the couplings onto the holder on the

attachment.

Connecting the multi connector system:

1.

Align the pins of the attachment connector with corresponding

holes of the loader connector. The multi connector will not

connect if the attachment connector is upside down.

2.

Connect and lock the multi connector by turning the lever towards

the loader.

The lever should move easily all the way to its locking position. If the lever does not slide smoothly, check the

alignment and position of the connector and clean the connectors. Also shut down the loader and release the

residual hydraulic pressure.