-|Transparent Guide|-

Ordering Information

This is only for reference, the actual product does not support all combinations.

For selecting the specified model, follow the Autonics website.

Select a model that matches the ordering information of the motor and the driver.

AiCA

-

D

-

❶

❷

A

-

❸

-

EC

❶ Frame size

Number: Frame size (mm)

❸ Motor type

No mark: Standard type

B: Built-in brake type

❷ Axial length

M: Medium

L: Long

Cautions during Installation

•

Install on the metal plate with high thermal conductivity for heat

dissipation of the driver.

•

Install in the well-ventilated area and install the cooling fan in the

unventilated environment.

•

Failure to heat dissipation may result in damage or malfunction

due to the stress on the product.

Check the environment of use within the specifications and

install on the well-heat dissipated area

•

In case of installing the drivers more than two, keep distance at

least 20 mm in horizontal direction and at least 25 mm in vertical

direction.

Horizontal direction:

≥ 20 mm

Vertic

al dir

ec

tion:

≥ 25 mm

Manual

For proper use of the product, refer to the manuals and be sure to follow the safety

considerations in the manuals.

Download the manuals from the Autonics website.

Sold Separately

•

I/O cable: CO20-MP□-R (specifications: AiC-EC TAG)

•

Motor + Encoder cable: C1D14M(B)-□ (fixed type), C1DF14M(B)-□ (flexible type)

Product Components

• Product

• Instruction manual

• Power connector × 1

•

I/O connector × 1

•

Brake connector (AiCA-D-B-EC Series) × 1

Cautions during Use

•

Follow instructions in ‘Cautions during Use’.

Otherwise, it may cause unexpected accidents.

• Install vertically so that the status display part is located on top.

•

In case of unwanted noise generating from peripherals and power, use ferrite core in the

wiring.

•

The thickness of cable should be same or thicker than the below specifications when

connecting the cable for connector.

- Motor + Encoder connector: AWG22

- Power connector: AWG18

- I/O connector: AWG28

- Brake connector: AWG22

•

Keep the distance between power cable and signal cable over 10 cm.

•

Do not input external signal until the driver is initialized (In-Position LED ON) after power is

applied.

•

Motor vibration and noise may occur in a specific frequency range.

- Change the motor installation method or attach the damper.

- Use the unit out of the corresponding frequency range due to changing motor RUN speed.

•

Maintain and inspect regularly the following lists.

- Unwinding bolts and connection parts for the unit installation and load connection

- Abnormal sound from ball-bearing of the unit

- Damage and stress of lead cable of the unit

- Connection error with motor

- Inconsistency between the axis of motor output and the center, concentric (eccentric,

declination) of the load, etc.

•

This product does not contain a protection function for a motor unit.

•

This unit may be used in the following environments.

- Indoors (in the environment condition rated in ‘Specifications’)

- Altitude max. 2,000 m

- Pollution degree 2

- Installation category II

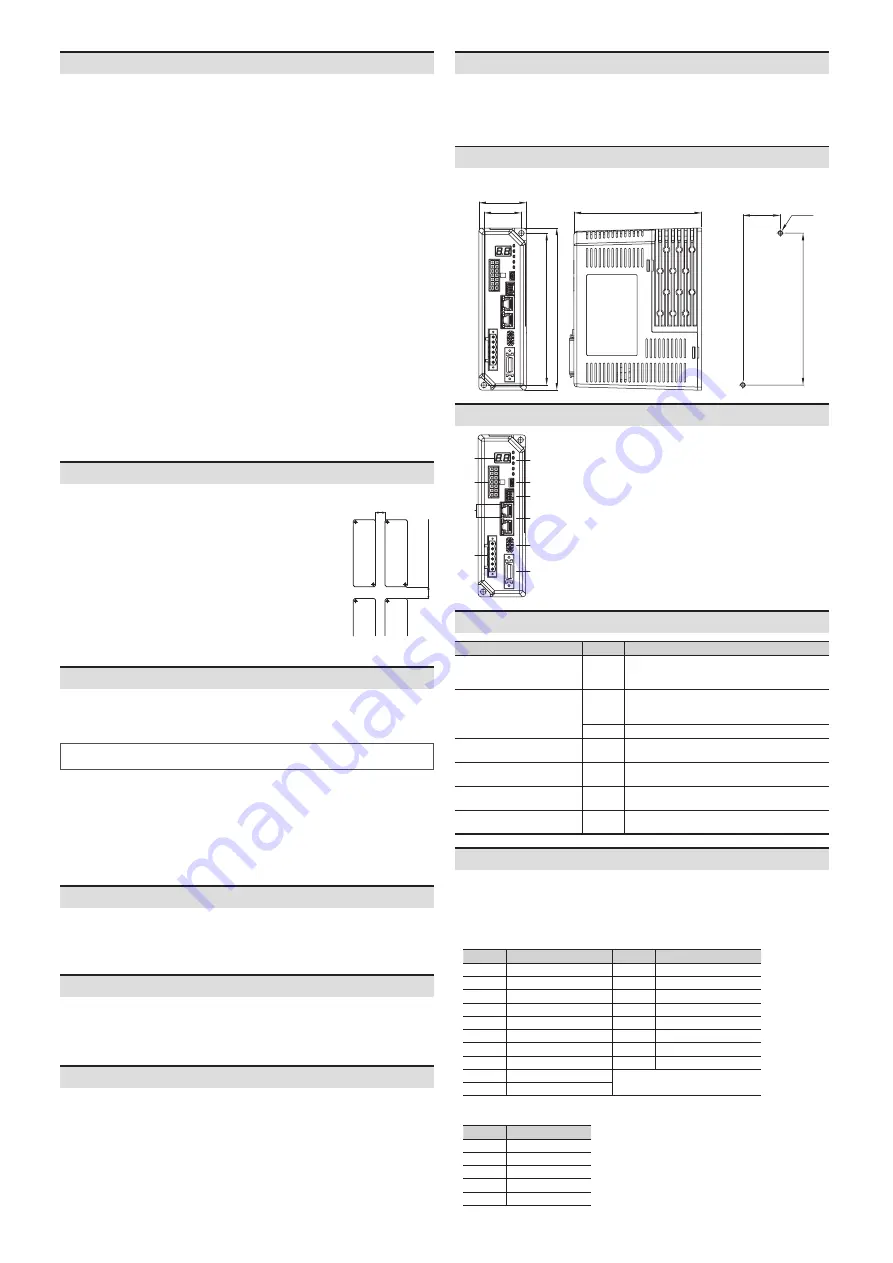

Unit Descriptions

09

06

07

05

03

04

01

08

02

10

01. Motor + Encoder connector

02. Power connector

03. Comm. connector

04.

I/O connector

05.

Brake connector (AiCA-D-B-EC Series)

06. USB connector

07.

Comm. ID setting rotary switch

08. Status display part

09. Status indicators

10. Comm. indicator

Dimensions

•

Unit: mm, For the detailed drawings, follow the Autonics website.

160

47

150

37

126

150

37

2-M5

Panel cut-out

Alarm / Warning

The status display part displays segment depending on Alarm / Warning type.

Depending on the alarm / warning type, it flashes for 0.4 sec interval and it turns OFF for 0.8 sec

repeatedly.

For more information of Alarm / Warning, refer to ‘User manual’.

■

Alarm

Display Alarm type

Display Alarm type

c5

EtherCAT comm. error

eA

Speed command error

e1

Overcurrent error

eB

Lack of voltage error

e2

Overspeed error

eC

In-Position error

e3

Position tracking error

eD

Memory error

e4

Overload error

eE

Emergency stop

e5

Overheat error

eH

Home search error

e6

Motor connection error

eJ

Brake connection error

e7

Encoder connection error

eK

PDO allocation error

e8

Overvoltage error

-

e9

Motor alignment error

■ Warning

Display Warning type

w1

+Software limit

w2

-Software limit

w3

+Hardware limit

w4

-Hardware limit

w5

Overload warning

Software

Download the installation file and the manuals from the Autonics website.

■

atMotion

The program allows to manage the motor driver's parameter setting and monitoring

data.

Status Display Part / Indicators

Display part / Indicator

Color

Descriptions

Status display part (7-segment)

Red

Displays EtherCAT ID

Displays the corresponding number, operation

when alarm / warning occurs

Power / Alarm indicator

(PWR/AL)

Green

Turns ON when the unit operates in normal after

power is applied

Flashes depending on the warning type

Red

Flashes depending on the alarm type

In-Position indicator (INP)

Yellow

Turns ON when motor is placed at command

position after positioning input

Servo ON / OFF indicator

(SERVO)

Blue

Turns ON when Servo ON, turns OFF when Servo

OFF

EtherCAT comm. error indicator

(ERR)

Red

Flashes depending on communication fail status

EtherCAT comm. operation

indicator

(RUN)

Green

Flashes depending on communication normal

status